Understanding what is chocolate viscosity proves essential for chocolatiers seeking consistent results in molding, enrobing, and decorating applications. Chocolate viscosity measures the resistance of melted chocolate to flow, directly impacting how easily chocolate coats confections, fills molds, and creates smooth surfaces. This comprehensive guide explores the science behind viscosity, factors affecting flow properties, and professional techniques for adjusting chocolate consistency to achieve perfect results across various applications.

Understanding Chocolate Viscosity Fundamentals

Chocolate viscosity represents the internal friction within melted chocolate that determines how freely it flows and spreads. Professional chocolatiers measure and control viscosity to ensure optimal performance in specific applications.

The Science Behind Flow Properties

What is chocolate viscosity from a scientific perspective relates to the interaction between cocoa particles, sugar crystals, and fat molecules suspended in cocoa butter. Higher viscosity indicates thicker, more resistant flow, while lower viscosity describes thin, fluid chocolate. Temperature, particle size, and fat content all influence these flow characteristics significantly.

The physics of chocolate viscosity involves both Newtonian and non-Newtonian behavior. At rest, chocolate exhibits higher resistance to flow, but once movement begins, viscosity decreases slightly. This property, called thixotropy, explains why stirring melted chocolate makes it flow more easily. Professional chocolate work requires understanding these behaviors to predict how chocolate performs during molding, coating, and decorating processes.

Why Viscosity Matters in Chocolate Work

Proper chocolate viscosity ensures successful execution across various techniques. Thick chocolate won't flow into intricate mold details or create smooth enrobed coatings, while excessively thin chocolate runs off products without adequate coverage. The Chocolate Mold Egg Facet 29mm CW1907 requires specific viscosity to capture delicate facet details, whereas larger pieces like the Chocolate Mold Egg Smooth 55mm CW2004 tolerate slightly thicker consistency.

|

Application |

Ideal Viscosity |

Why It Matters |

|

Mold Filling |

Medium-Low |

Flows into details, releases air bubbles |

|

Enrobing |

Medium |

Even coating without excessive dripping |

|

Hand Dipping |

Medium-High |

Clings to centers, creates proper thickness |

|

Piping Details |

High |

Holds shape, creates defined lines |

|

Spray Application |

Very Low |

Atomizes properly through equipment |

Factors Affecting Chocolate Viscosity

Multiple variables influence what is chocolate viscosity in practical applications, with some factors controllable and others inherent to chocolate composition.

Temperature's Critical Role

Temperature dramatically affects chocolate viscosity by altering cocoa butter's fluidity. Warmer chocolate flows more easily as cocoa butter becomes less viscous, while cooler chocolate thickens and resists flow. Dark chocolate works optimally at 88-90°F (31-32°C), milk chocolate at 86-88°F (30-31°C), and white chocolate at 82-84°F (28-29°C) when properly tempered.

Exceeding recommended temperatures reduces chocolate viscosity excessively, causing chocolate to run off products without adequate coating. Temperatures below optimal range increase viscosity dramatically, creating thick chocolate that won't flow into detailed molds properly. A Digital Thermometer with Immersion Probe monitors temperature precisely, ensuring consistent viscosity throughout production.

Cocoa Butter Content

Fat percentage directly determines what is chocolate viscosity in any given chocolate. Higher cocoa butter content creates lower viscosity, producing chocolate that flows more freely. Couverture chocolate contains minimum 31% cocoa butter, providing excellent flow properties for professional applications. The Dark Chocolate 55% Venezuela demonstrates optimal fat content for versatile use.

Lower fat chocolates exhibit higher chocolate viscosity, requiring temperature adjustments or added cocoa butter to achieve proper flow. Natural Cocoa Butter 100% can be incorporated to thin chocolate without compromising temper, typically at 1-5% of total chocolate weight. This adjustment proves particularly useful when working with compound chocolate that may exhibit excessive thickness.

Particle Size Distribution

The fineness of cocoa and sugar particles significantly impacts chocolate viscosity. Finely ground particles with smooth surfaces flow more easily than coarse particles with irregular shapes. Industrial refining processes like conching reduce particle size while coating particles with fat, both actions decreasing viscosity.

Chocolate containing larger particles requires more cocoa butter to maintain equivalent flow properties. This explains why artisan chocolates made with less refined cacao sometimes exhibit higher chocolate viscosity than commercial products. Professional production facilities use equipment like the FBM Rumbo Chocolate Grinder to control particle size precisely.

Moisture and Lecithin Content

Even minute moisture amounts dramatically increase what is chocolate viscosity by causing chocolate to seize. Water molecules interact with sugar creating thick, grainy mixture that won't flow properly. Strict moisture control proves essential throughout chocolate handling and storage.

Lecithin, an emulsifier derived from soy or sunflower, reduces chocolate viscosity significantly. Adding 0.2-0.5% lecithin by weight decreases viscosity substantially without altering chocolate's temper or flavor profile. This addition proves particularly valuable when working with chocolate in enrobing applications requiring consistent flow properties.

Measuring Chocolate Viscosity

Professional chocolatiers measure chocolate viscosity using standardized methods ensuring consistent product quality and performance.

Professional Measurement Tools

Laboratory viscometers provide precise chocolate viscosity measurements using rotating spindles or falling spheres. The Casson model, specific to chocolate rheology, accounts for chocolate's unique flow behavior. Industrial operations typically measure viscosity in Poise or Pascal-seconds, with typical chocolate ranging from 10-50 Poise depending on composition and application.

For small-scale operations, the spatula test provides practical assessment of what is chocolate viscosity without expensive equipment. Dip a Professional Spatula into tempered chocolate and lift it out. Properly viscous chocolate flows off in smooth ribbon that mounds slightly before leveling. Excessively thick chocolate drops in chunks, while overly thin chocolate runs off immediately without forming ribbon.

Practical Assessment Methods

The drip test evaluates chocolate viscosity functionally for specific applications. Pour small amount of chocolate from measured height onto parchment paper. Properly viscous chocolate for molding spreads to consistent diameter before stopping. Time required for drip to cease indicates viscosity level appropriate for intended use.

Temperature consistency during testing proves critical as viscosity changes rapidly with temperature fluctuations. Conduct tests at intended working temperature using Chocolate Melters that maintain stable heat throughout assessment periods.

Adjusting Chocolate Viscosity

Chocolatiers employ various techniques to modify chocolate viscosity for specific applications, from thinning thick chocolate to creating more viscous consistency.

Methods for Reducing Viscosity

What is chocolate viscosity reduction involves several approaches depending on chocolate type and intended use. Adding cocoa butter remains the most effective method, introducing pure fat that decreases internal friction without affecting temper. Add Cocoa Butter 100% Venezuelan Fine Cacao in 1-2% increments, stirring thoroughly and testing flow between additions.

|

Adjustment Method |

Amount |

Best For |

Considerations |

|

Cocoa Butter |

1-5% by weight |

All chocolate types |

Maintains temper, adds richness |

|

Lecithin |

0.2-0.5% by weight |

Enrobing, molding |

Powerful effect, use sparingly |

|

Temperature Increase |

2-4°F above working temp |

Quick adjustments |

Monitor carefully, avoid overheating |

|

Vegetable Oil |

1-3% (compound only) |

Compound chocolate |

Never use with tempered chocolate |

Lecithin addition powerfully reduces chocolate viscosity, making chocolate more fluid with minimal quantity. Add liquid lecithin drop by drop, mixing thoroughly between additions. Excessive lecithin creates overly fluid chocolate that won't coat properly or form stable structures in 3D chocolate molds.

Increasing Chocolate Thickness

Situations requiring higher chocolate viscosity demand different approaches. Cooling chocolate slightly increases viscosity without compromising temper, effective when chocolate flows too freely during hand dipping or piping applications. Lower temperature by 2-3°F, stirring constantly to maintain even heat distribution.

Adding finely ground cocoa powder increases what is chocolate viscosity while intensifying chocolate flavor. Sift Natural Fine Venezuelan Cocoa Powder into melted chocolate in 1% increments, whisking thoroughly to prevent lumps. This method works particularly well for creating piping chocolate that holds detailed designs.

Viscosity Requirements for Different Applications

Understanding chocolate viscosity needs for specific techniques ensures optimal results across various chocolate applications.

Molding Requirements

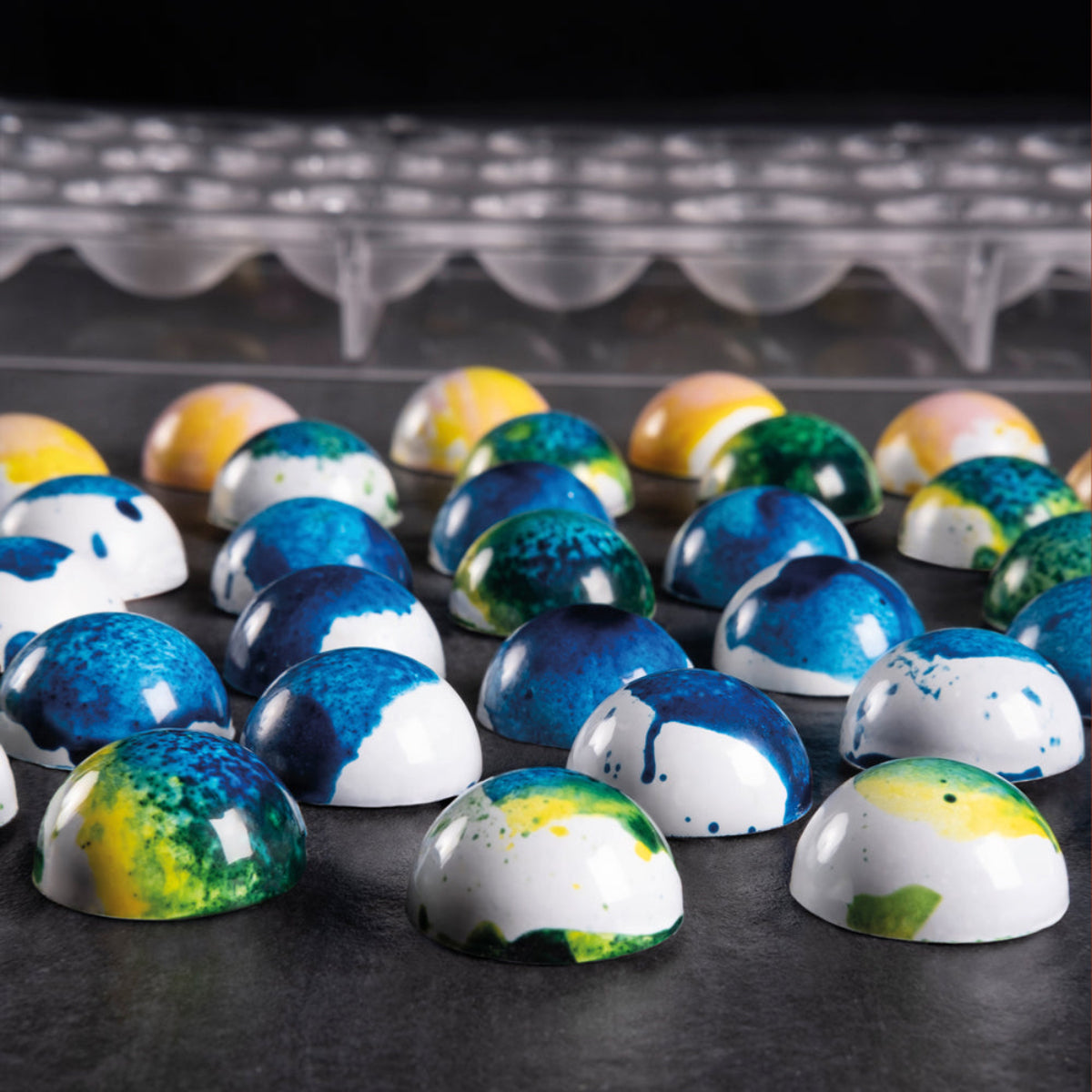

Chocolate viscosity for molding must allow chocolate to flow into intricate details while releasing trapped air easily. Medium-low viscosity works best for detailed polycarbonate molds, flowing into fine features like the Chocolate Mold Lips Facet CW1937 requires. Slightly higher viscosity suits simpler shapes like half-sphere molds.

Vibrating or tapping filled molds releases air bubbles trapped by chocolate viscosity, essential for professional finish. The Chocolate Mould Dancing Square CW12106 showcases how proper viscosity captures geometric precision without air pockets. Magnetic molds like the Chocolate Mould Magnetic Moose HM020 benefit from slightly lower viscosity ensuring complete cavity filling.

Enrobing Applications

Enrobing requires carefully controlled what is chocolate viscosity to create even coatings without excessive buildup or thin spots. Medium viscosity allows chocolate to coat confection centers completely while excess drains away cleanly. Enrobing equipment maintains precise temperature controlling viscosity throughout production runs.

Too thick chocolate creates heavy coatings with poor appearance, while excessively thin chocolate viscosity runs off centers without adequate coverage. Professional operations using enrobing stations monitor viscosity constantly, adjusting temperature and adding cocoa butter as needed to maintain optimal flow.

Spraying and Airbrushing

Spray applications demand lowest chocolate viscosity allowing chocolate to atomize properly through equipment. The KREA Swiss HOTCHOC heated airless spray gun maintains chocolate at precise temperature ensuring consistent viscosity during application. Cocoa butter spraying, popular for coloring chocolate molds, requires even lower viscosity achieved by warming colored cocoa butter above typical working temperatures.

Airbrush systems create velvet effects and gradient colorations impossible with thicker chocolate. Proper what is chocolate viscosity for spraying allows fine mist application building coverage gradually. Products like Velvet Effect Spray demonstrate results achievable with correctly adjusted viscosity for spray applications.

Troubleshooting Viscosity Problems

Common chocolate viscosity issues require systematic diagnosis and targeted solutions ensuring consistent chocolate performance.

Chocolate Too Thick

Excessively high chocolate viscosity prevents proper flow into molds and creates uneven coatings. First verify temperature using accurate thermometer; cold chocolate naturally exhibits higher viscosity. Bring chocolate to proper working temperature before attempting other corrections.

If temperature proves correct but what is chocolate viscosity remains too high, add small amounts of cocoa butter. Mix thoroughly and test flow after each addition. For compound chocolate, vegetable oil provides alternative, though this compromise affects flavor and texture. Never add oil to tempered couverture chocolate as this ruins crystallization structure.

Chocolate Too Thin

Overly low chocolate viscosity causes chocolate to run off products without forming proper coatings. Reduce temperature slightly, cooling chocolate by 2-3°F while stirring constantly. This increases viscosity without risking temper loss. Monitor temperature carefully using precision equipment avoiding excessive cooling that causes chocolate to thicken unevenly.

If temperature adjustment proves insufficient, add cocoa powder or reduce fat content in future batches. For immediate correction, blend small amount of properly tempered chocolate at correct viscosity into thin batch, raising overall chocolate viscosity to workable level.

Seized or Grainy Chocolate

Water contact causes chocolate to seize, dramatically increasing what is chocolate viscosity and creating grainy texture. Small moisture amounts sometimes respond to gentle heating and vigorous stirring incorporating water more completely. For severely seized chocolate, add warm cream gradually creating ganache rather than discarding the batch.

Prevention proves simpler than correction. Ensure all equipment remains completely dry, use moisture-free scrapers and spatulas, and protect chocolate from steam during melting. Store chocolate properly in airtight containers preventing moisture absorption.

Professional Production Considerations

Large-scale chocolate production requires systematic chocolate viscosity management ensuring product consistency across batches and production runs.

Batch-to-Batch Consistency

Maintaining uniform chocolate viscosity across multiple production batches demands careful ingredient selection and processing control. Source chocolate from consistent suppliers providing detailed specifications. The Venezuelan chocolate products offer reliable performance when sourced consistently.

Document all what is chocolate viscosity adjustments including cocoa butter additions, lecithin quantities, and temperature variations. This record keeping identifies patterns affecting chocolate behavior, allowing proactive adjustments preventing issues before they impact production. Professional tempering equipment maintains consistent conditions reducing batch-to-batch variation.

Equipment Impact on Viscosity

Processing equipment significantly affects chocolate viscosity through heating, mixing, and particle size reduction. Chocolate melters maintaining precise temperature control prevent viscosity fluctuations during extended production. The Pavoni Minitemper 110V automates temperature management ensuring consistent chocolate viscosity without constant monitoring.

Mixing equipment affects chocolate structure through shear forces and aeration. Gentle mixing preserves temper while maintaining viscosity, whereas aggressive stirring may thin chocolate temporarily through shear-thinning effects. Understanding equipment impact allows chocolatiers to predict and control what is chocolate viscosity throughout processing stages.

Quality Control Testing

Implement regular chocolate viscosity testing throughout production ensuring specifications remain within acceptable ranges. Simple flow tests using standardized procedures identify deviations before they affect finished product quality. Many operations test viscosity hourly during active production, making immediate corrections when measurements fall outside target ranges.

Temperature monitoring proves critical for viscosity control. Install multiple thermometers throughout production areas verifying chocolate maintains proper temperature from tempering through molding or enrobing. The Cooled Working Table provides climate-controlled surface maintaining ideal chocolate working conditions regardless of ambient temperature.

Advanced Viscosity Management Techniques

Expert chocolatiers employ sophisticated approaches to chocolate viscosity control achieving specialized effects and solving complex production challenges.

Creating Custom Viscosity Profiles

Different products within single production facility may require distinct what is chocolate viscosity specifications. Develop custom formulations for each application, adjusting cocoa butter content, lecithin levels, and particle size distributions. Document these recipes precisely enabling consistent reproduction across production runs.

Seasonal temperature variations affect chocolate viscosity management strategies. Summer production typically requires less added cocoa butter than winter operations due to warmer ambient conditions. Adjust base formulations seasonally rather than making constant real-time corrections during production.

Working With Specialty Chocolates

Ruby chocolate, blonde chocolate, and other specialty varieties exhibit unique chocolate viscosity characteristics requiring modified handling techniques. Ruby chocolate formulations often demonstrate higher viscosity than traditional dark chocolate necessitating temperature or cocoa butter adjustments.

Single-origin chocolates like those made from Venezuelan cacao beans vary in what is chocolate viscosity based on bean origin and processing methods. Test each chocolate source individually establishing optimal working parameters rather than assuming consistent behavior across origins.

Incorporating Inclusions

Adding nuts, fruits, or other inclusions affects chocolate viscosity by introducing additional particle mass and often moisture content. Ensure all inclusions are completely dry before incorporation preventing chocolate seizure. Toast nuts like those used in praline chocolates removing residual moisture that would increase chocolate viscosity undesirably.

Mix inclusions into chocolate at proper temperature maintaining overall viscosity suitable for intended application. Excessive inclusions raise viscosity significantly, requiring cocoa butter addition compensating for reduced flow properties. Plan inclusion percentages considering final viscosity requirements for molding or other processes.

Conclusion

Mastering what is chocolate viscosity and understanding chocolate viscosity management proves fundamental to professional chocolate work across all applications. Successful viscosity control requires monitoring temperature precisely, understanding ingredient impacts, and making systematic adjustments that achieve optimal flow properties for specific techniques. Whether filling intricate molds, creating smooth enrobed coatings, or developing custom chocolate formulations, the principles outlined provide comprehensive foundation for viscosity mastery. Explore professional chocolate equipment, premium couverture, and specialized tools at Zucchero Canada to elevate your chocolate crafting with precise viscosity control.

References

Beckett, S. T. (2023). The science of chocolate (3rd ed.). Royal Society of Chemistry.

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). John Wiley & Sons.

KREA Swiss. (2024). Professional food equipment and spray systems. https://kreaswiss.com/food-equipment

Pavoni Italia. (2024). Professional color collections for chocolate applications. https://pavonitalia.com/en/collections/professional-collezioni-colori-e-materie-prime

Talbot, G. (2024). Chocolate temper and viscosity management. In Science and Technology of Enrobed and Filled Chocolate, Confectionery and Bakery Products. Woodhead Publishing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.