The craft of bean to bar chocolate making has evolved from an exclusively industrial process to an accessible artisan pursuit, thanks to modern chocolate making machines designed for smaller-scale producers. Creating chocolate from raw cacao beans requires specialized equipment that can handle multiple transformation stages—from cracking and winnowing to refining and conching. Understanding the complete bean to bar process reveals why dedicated machinery proves essential for chocolatiers seeking to control every aspect of flavor development and texture, enabling them to express the unique characteristics of different cacao origins.

Essential Bean to Bar Chocolate Machines

Chocolate Grinders and Refiners

Grinding equipment represents the heart of bean to bar chocolate making. A chocolate grinding machine breaks down cacao nibs into progressively smaller particles while generating friction heat that melts cocoa butter, transforming solid nibs into flowing liquid chocolate. Stone melangers excel at this task, using granite wheels that grind nibs between rotating and stationary surfaces.

The FBM Rumbo Chocolate Grinder offers substantial capacity for growing operations with its robust construction and precise controls, while the FBM Rumbo Kid Chocolate Grinder suits artisan producers with more modest volume requirements. The Taobroma Ball Mill Grinder demonstrates how advanced speed control optimizes different processing phases within a single machine.

Cracking and Winnowing Systems

Cracking and winnowing machines separate roasted cacao beans into nibs and shells, a step that proves tedious and time-consuming by hand. Dedicated equipment becomes essential for any production beyond experimental batches. The Ninja Kid Cracker Winnower efficiently processes beans while removing papery shells that would create bitter off-flavors in finished chocolate.

Integrated Melting and Conching Equipment

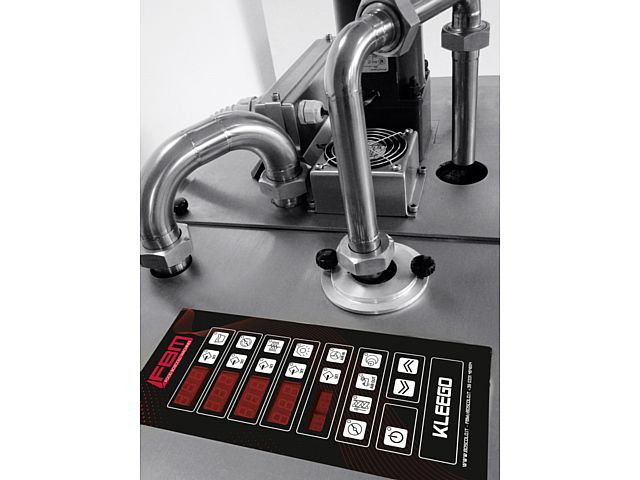

Some modern equipment combines multiple functions for streamlined production. The FBM Kleego 50 Chocolate Melter Conche offers integrated functionality suitable for operations seeking efficiency without multiple machines, while the FBM Kleego 100 provides expanded capacity for higher-volume producers.

Professional Tempering Equipment

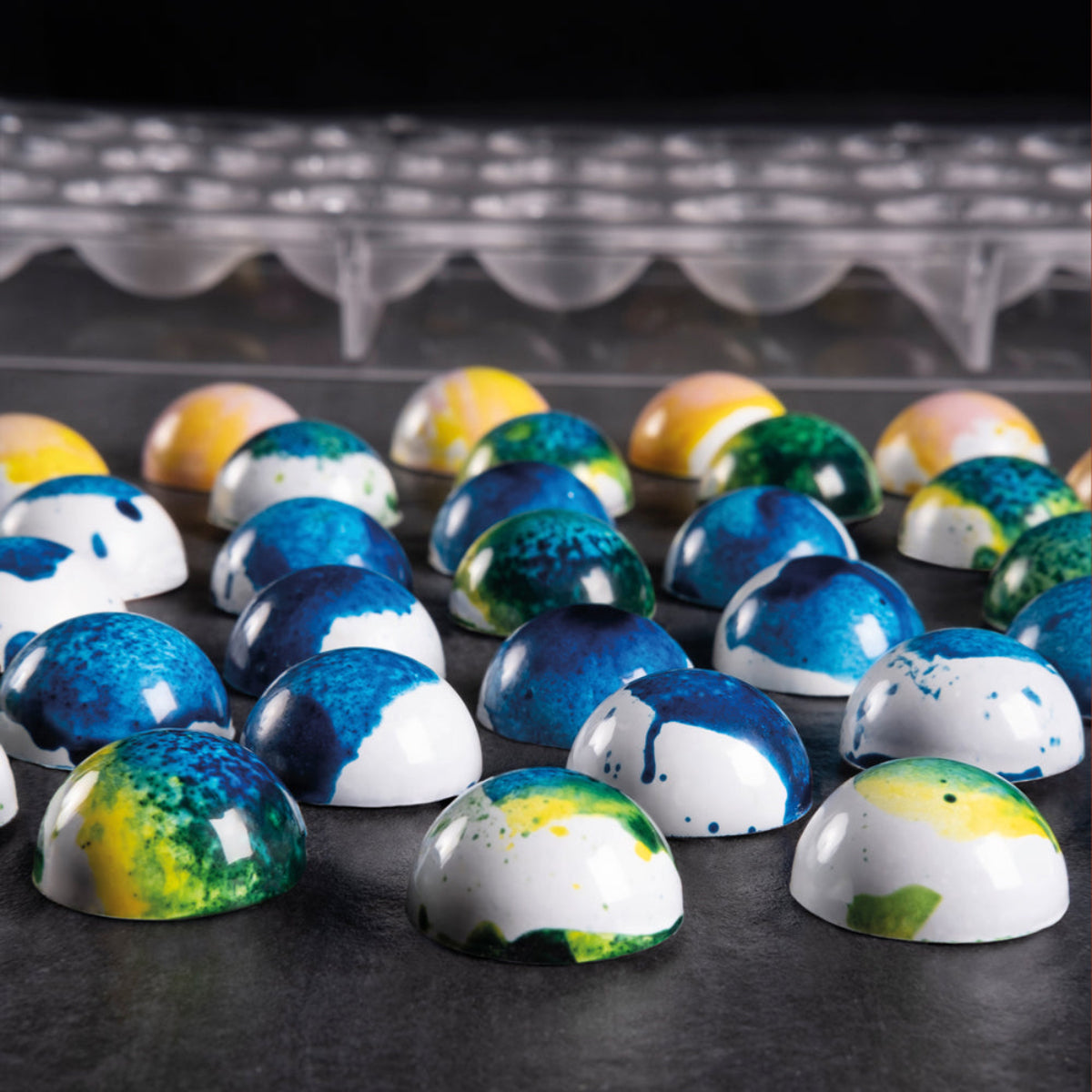

While technically post-production, tempering machines prove essential for bean to bar operations selling molded bars or bonbons. The Aura Tabletop Tempering Machine provides compact professional tempering for smaller producers, ensuring proper cocoa butter crystal structure for glossy, snap-perfect chocolate bars.

Selecting Bean to Bar Equipment: Key Considerations

Determine Your Target Production Capacity

Start by defining your target production volume—how many kilograms of finished chocolate do you need weekly or monthly? This calculation determines minimum equipment capacity and helps identify models that match your scale without excessive overcapacity. Small-batch artisan producers working with 5-10 kg batches need different equipment than operations processing 50+ kg daily. Right-sizing equipment prevents overinvestment while avoiding bottlenecks that limit growth as your business expands.

Align Equipment with Your Chocolate Products

Product focus influences equipment selection significantly. Producers making primarily dark chocolate have simpler equipment needs than those producing milk or white chocolate, which require additional ingredients and often more extensive conching periods. If you plan to create inclusion bars with nuts or fruit, consider equipment that accommodates adding ingredients during late conching stages. Understanding conching chocolate techniques helps producers optimize equipment use for desired flavor outcomes and texture development.

Build Your Complete Production Setup

Budget allocation should account for the complete equipment chain, not just individual machines. A high-quality melanger proves useless without proper roasting equipment and winnower to prepare the beans. Consider phasing equipment purchases—perhaps starting with a versatile melanger that handles grinding, refining, and conching in one vessel, then adding dedicated refiners or conches as production scales. Our comprehensive bean to bar machines collection showcases various capacity options matching different production scales.

Evaluate Space and Facility Requirements

Measure available floor space carefully, accounting for operational clearances, ingredient storage, and workflow patterns. Tabletop melangers fit compact spaces but limit batch sizes, while floor-standing models demand dedicated areas but offer superior capacity and ergonomics for extended operation. Technical considerations include electrical requirements and cooling needs, as larger equipment may require 240V circuits or three-phase power not standard in all facilities.

Source Quality Raw Materials

Success depends not just on equipment but on quality ingredients. Starting with premium beans makes all the difference in final chocolate quality. Consider sourcing options like Venezuelan cacao beans for their exceptional flavor profiles that showcase fruity, nutty, and complex flavor notes unique to different growing regions.

Advantages of Bean to Bar Chocolate Production

Complete Control Over Flavor Development

Producing chocolate from bean to bar offers chocolatiers unprecedented control over their final product. Flavor customization becomes possible when you select specific cacao origins and control roasting profiles, grinding times, and conching durations. This control allows you to highlight fruity notes in Madagascar beans or emphasize earthy characteristics in Ecuadorian varieties—distinctions that disappear when working solely with pre-manufactured chocolate.

Long-Term Cost Savings and ROI

Cost efficiency emerges as production scales increase. While initial equipment investment appears substantial, raw cacao beans cost significantly less per kilogram than finished couverture chocolate. A chocolate refiner processing beans in-house reduces ingredient costs by 40-60% compared to purchasing equivalent quality finished chocolate. These savings compound over time, allowing reinvestment in premium bean sources or additional equipment to expand your product line.

Create Unique Brand Identity and Customer Loyalty

Brand differentiation strengthens dramatically when you control the entire production chain. Customers increasingly value transparency and craftsmanship, willing to pay premium prices for authentic bean to bar chocolate. Your story becomes richer when you can discuss specific farms, harvest seasons, and processing techniques. This narrative elevates your products beyond commodity chocolate, justifying higher margins while building customer loyalty through authentic connection to source.

Maintain Batch-to-Batch Quality Consistency

Quality consistency improves when you manage all variables from start to finish. Pre-made chocolate varies between batches as manufacturers adjust formulations or source from different suppliers. Professional equipment processing your own beans delivers identical results when you maintain consistent processes and bean sources. This reliability proves crucial for maintaining signature products that customers expect to taste the same every time.

Professional-Grade Features That Drive Results

Professional-grade bean to bar equipment distinguishes itself through heavy-duty motors and drive systems that handle the demanding work of grinding dense cacao nibs for hours without overheating or failure. Temperature control mechanisms maintain optimal processing conditions throughout grinding and conching, with digital controllers displaying real-time temperatures for precise adjustments. Stone roller materials using dense, non-porous granite that doesn't absorb flavors ensure clean processing between batches while variable speed controls allow operators to adjust grinding intensity throughout different process stages.

Partner with Zucchero Canada for Your Bean to Bar Journey

Successfully producing bean to bar chocolate requires more than just equipment—it demands understanding the complex transformations that occur during processing. Investing in proper bean to bar equipment provides the tools, but developing recipes and techniques takes time and experimentation. Each cacao origin responds differently to roasting, grinding, and conching, requiring producers to adjust parameters and processing times to achieve optimal results.

The chocolate machines available today make artisan chocolate production more accessible than ever, enabling small producers to create products rivaling those from established manufacturers. Combined with quality ingredients and proper technique, professional equipment transforms passionate chocolate makers into successful artisan producers who can compete in an increasingly sophisticated market.

At Zucchero Canada, we support bean to bar chocolate makers with carefully selected equipment from proven manufacturers. Our range spans entry-level machines for aspiring chocolatiers to production-scale equipment for established operations. We understand the unique challenges of starting and scaling chocolate production, offering not just machinery but the knowledge to use it effectively for long-term success.

Explore our comprehensive collection to find equipment matching your production goals and budget. Whether you're launching your first bean to bar venture or expanding existing capacity, our team provides expert guidance on equipment selection, setup, and operation. For detailed specifications, capacity recommendations, or assistance planning your complete production workflow, contact our knowledgeable staff who understand both the technical and practical aspects of artisan chocolate making.

Visit zuccherocanada.ca or reach out directly to discuss your bean to bar equipment needs. We're committed to supporting your chocolate-making journey with quality machinery, expert advice, and ongoing support as your operation grows and evolves.