Maintaining the ideal humidity for storing chocolate proves essential for preserving quality, preventing bloom, and extending shelf life of both finished confections and raw chocolate ingredients. This comprehensive guide reveals professional methods for controlling humidity in chocolate storage environments, diagnosing moisture-related problems, and implementing systems ensuring optimal conditions for everything from raw cacao beans to finished molded chocolates.

Understanding Humidity's Impact on Chocolate

The Science of Sugar Bloom

Excessive humidity causes sugar bloom, the most common moisture-related chocolate defect. When humidity exceeds recommended levels, moisture condenses on chocolate surfaces dissolving surface sugar. As humidity normalizes, dissolved sugar recrystallizes forming white, grainy coating that mars appearance and texture. Unlike fat bloom which sometimes reverses through re-tempering, sugar bloom permanently damages chocolate requiring remelting and remolding.

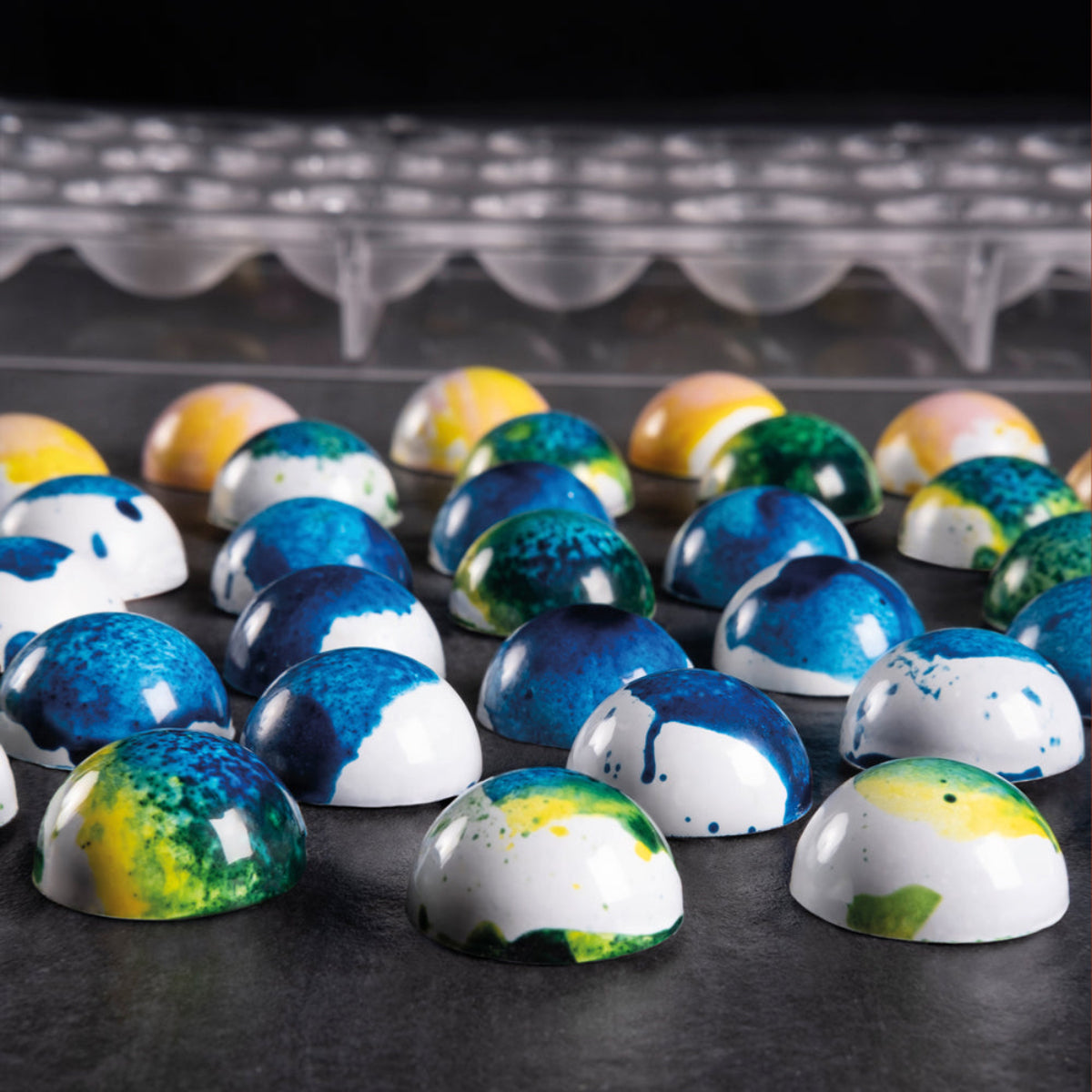

Sugar bloom affects professional chocolate work significantly. Molded chocolates develop unsightly white patches destroying glossy finish. Enrobed confections show streaky surfaces while chocolate decorations lose definition. Proper storage maintains the geometric precision achievable only when ideal humidity prevents moisture interference.

Moisture and Chocolate Structure

Chocolate's complex crystalline structure remains stable only within specific humidity parameters. The ideal humidity prevents moisture from disrupting cocoa butter crystallization patterns responsible for chocolate's snap and glossy finish. Even small moisture amounts can initiate chain reactions destabilizing entire batches.

|

Humidity Level |

Impact on Chocolate |

Visible Signs |

Reversibility |

|

Below 40% |

Excessive drying, potential cracking |

Surface cracks, brittleness |

Irreversible structural damage |

|

40-50% (Ideal) |

Optimal stability |

Glossy finish, proper snap |

N/A - maintained quality |

|

50-60% |

Increased bloom risk |

Slight dulling |

Preventable with quick correction |

|

Above 60% |

Severe sugar bloom |

White coating, grainy texture |

Irreversible without remelting |

Professional storage facilities use climate-controlled equipment maintaining precise humidity levels. Controlled environment equipment protects products during production and initial storage phases.

Optimal Humidity Ranges for Different Chocolate Types

Dark Chocolate Storage

Dark chocolate tolerates humidity variations better than milk or white varieties due to lower sugar and milk solid content. The ideal humidity for dark varieties ranges 40-50%, with 45% representing optimal midpoint. High-quality dark chocolate like Dark Chocolate 55% Venezuela maintains quality longest within these parameters.

Single-origin dark chocolates demand stricter humidity control than blended varieties. Fine flavor characteristics from beans like Rio Caribe Superior Origin Venezuela express fully only when storage conditions prevent moisture interference with delicate flavor compounds. Professional chocolatiers working with premium ingredients invest in precise environmental control protecting flavor investments.

Milk and White Chocolate Considerations

Milk chocolate requires more stringent ideal humidity control than dark varieties. Higher milk solid and sugar content increases hygroscopic properties making milk chocolate more susceptible to moisture absorption. Maintain 40-45% humidity, trending toward lower end of range for products like FCH Milk Chocolate Latin American Origin 44%.

White chocolate proves most moisture-sensitive requiring ideal humidity below 45%. FCH White Chocolate Latin American Origin 28% contains no cocoa solids, making sugar and milk solids primary components. These ingredients absorb moisture readily causing rapid bloom development and flavor degradation when humidity exceeds recommended levels.

Raw Cacao and Cocoa Products

Raw cacao beans store optimally at slightly different humidity than finished chocolate.

|

Product Type |

Ideal Humidity |

Storage Duration |

Container Type |

|

Raw Cacao Beans |

50-60% |

12-18 months |

Breathable bags |

|

Cocoa Powder |

40-50% |

18-24 months |

Airtight containers |

|

Cocoa Butter |

Below 50% |

24-36 months |

Sealed blocks |

|

Cocoa Liquor |

40-50% |

18-24 months |

Vacuum-sealed |

|

Cacao Nibs |

45-55% |

12-18 months |

Airtight jars |

Peruvian Cocoa Beans and other fermented dried beans require 50-60% humidity preventing excessive drying while avoiding mold growth. This higher range maintains beans' natural moisture content without encouraging fungal development.

Cocoa powder demonstrates different ideal humidity requirements than solid chocolate. Natural Fine Venezuelan Cocoa Powder requires 40-50% humidity with airtight container storage preventing clumping. Dutched Alkalized Cacao Powder shows similar requirements though alkalization process makes it slightly less hygroscopic than natural varieties.

Cocoa Butter 100% tolerates wider humidity variations than chocolate since it contains no sugar or milk solids. However, maintaining ideal humidity levels below 50% prevents oxidation and rancidity development accelerated by moisture presence.

Temperature and Humidity Relationship

Understanding ideal humidity requires considering temperature's influence on relative humidity and moisture condensation.

Relative Humidity Explained

Relative humidity measures air's moisture content relative to maximum capacity at given temperature. Warmer air holds more moisture than cooler air, meaning identical absolute moisture content produces different relative humidity percentages at various temperatures. This relationship critically affects ideal humidity in spaces experiencing temperature fluctuations.

When warm, humid air contacts cold chocolate surfaces, moisture condenses instantly causing sugar bloom. This phenomenon occurs when removing chocolate from refrigeration into warm environments or when uninsulated storage areas experience temperature swings. Professional storage maintains consistent temperature eliminating condensation risk regardless of ambient conditions.

Coordinating Temperature and Humidity

The ideal humidity of 40-50% coordinates with optimal temperature range of 60-65°F (15-18°C).

|

Storage Parameter |

Optimal Range |

Acceptable Range |

Warning Signs |

|

Temperature |

60-65°F (15-18°C) |

55-70°F (13-21°C) |

Softening, melting |

|

Relative Humidity |

40-50% |

35-55% |

White coating, dullness |

|

Air Circulation |

Gentle, consistent |

Moderate |

Uneven temperature zones |

|

Light Exposure |

Dark/minimal |

Low indirect |

Fading, fat oxidation |

This combination maintains chocolate stability while preventing moisture condensation. Temperatures below 60°F risk fat bloom through improper cocoa butter crystallization, while temperatures above 70°F cause softening and potential melting.

Professional chocolate storage facilities use integrated climate control systems simultaneously managing temperature and humidity. Comprehensive environmental management solutions suit commercial operations requiring precise control over both parameters protecting inventory investments.

Monitoring and Controlling Storage Humidity

Humidity Monitoring Equipment

Hygrometers measure relative humidity enabling verification of ideal humidity conditions. Digital hygrometers with data logging provide continuous monitoring revealing humidity fluctuations occurring when facilities are unattended. Place multiple hygrometers throughout storage areas since humidity varies by location; corners and near doors often show different readings than room centers.

Calibrate hygrometers regularly using salt test or calibration kits ensuring accuracy. Inaccurate readings lead to inappropriate interventions potentially harming chocolate despite apparent compliance with ideal humidity parameters. Professional operations maintain backup hygrometers verifying primary device accuracy through comparison.

Humidity Control Methods

|

Control Method |

Application |

Capacity |

Cost |

Best For |

|

Dehumidifier |

Reduces moisture |

30-70 pints/day |

$ |

Humid climates, summer |

|

Humidifier |

Adds moisture |

1-12 gallons/day |

$ |

Dry climates, winter |

|

Silica Gel Packets |

Passive absorption |

Small containers |

$ |

Individual packaging |

|

HVAC Integration |

Full control |

Whole facility |

$$ |

Professional operations |

|

Climate-Controlled Room |

Comprehensive |

Large inventory |

$$ |

Commercial production |

Dehumidifiers reduce excess moisture when ambient humidity exceeds ideal humidity levels. Select appropriately sized units for storage volume; undersized dehumidifiers run continuously without achieving target humidity while oversized units cycle excessively causing humidity fluctuations. Position dehumidifiers allowing air circulation throughout storage space rather than creating localized dry zones.

Humidifiers add moisture when ambient conditions fall below ideal humidity minimums. Desert climates and heated winter environments often require humidification preventing chocolate from drying excessively. Use evaporative humidifiers rather than mist-generating ultrasonic models; water droplets from ultrasonic humidifiers can contact chocolate causing localized moisture damage.

Silica gel packets provide passive humidity control within sealed containers. These desiccants absorb excess moisture maintaining stable ideal humidity in smaller spaces like shipping containers or display cases. Replace silica gel when saturation indicators show absorption capacity exhaustion, typically every 2-3 months depending on ambient conditions.

Storage Solutions for Optimal Humidity

Commercial Storage Systems

Professional chocolate operations require dedicated climate-controlled storage. Walk-in coolers with humidity control maintain precise ideal humidity across large inventory volumes. Professional cooling equipment provides workspace and storage combination ideal for production facilities requiring controlled environments during chocolate work and subsequent storage.

Sealed storage rooms with HVAC systems designed specifically for chocolate storage offer comprehensive environmental control. These systems maintain temperature, humidity, and air circulation simultaneously, eliminating hot spots and moisture pockets that develop in inadequately designed spaces. Investment in professional storage infrastructure protects chocolate inventory representing significant capital tied up in perishable products.

Small-Scale Storage Options

Home chocolatiers and small businesses achieve ideal humidity through careful space selection and supplemental equipment. Basements typically maintain cooler temperatures than upper floors but often suffer from excessive humidity requiring dehumidification. Interior closets away from exterior walls avoid temperature fluctuations while maintaining more stable humidity than spaces with windows or doors leading outside.

Airtight containers provide microenvironment control within less-than-ideal storage spaces. Food-grade plastic containers with silica gel packets create stable ideal humidity conditions protecting small quantities. Our display and storage solutions offer both presentation and protection features suitable for finished chocolates requiring controlled environments.

Packaging Considerations

Packaging materials significantly impact humidity exposure during storage. Foil wrapping provides excellent moisture barrier protecting individual chocolates from humidity fluctuations. Plastic film offers some protection though less effective than foil for long-term ideal humidity maintenance. Paper wrapping provides minimal moisture barrier and should be supplemented with outer protective layers.

Vacuum sealing removes air creating near-perfect ideal humidity environment for long-term storage. This technique suits raw ingredients like cacao nibs and cocoa powder stored for extended periods. Avoid vacuum sealing delicate molded chocolates; pressure can damage decorative details and fragile structures.

Seasonal Humidity Challenges

Seasonal Storage Strategy Comparison

|

Season |

Typical Humidity |

Primary Challenge |

Control Strategy |

Equipment Needs |

|

Spring |

50-70% (variable) |

Fluctuating conditions |

Active monitoring |

Dehumidifier on standby |

|

Summer |

60-80%+ |

Excessive moisture |

Continuous dehumidification |

Heavy-duty dehumidifier |

|

Fall |

40-60% (variable) |

Transition instability |

Flexible adjustment |

Both humidifier/dehumidifier |

|

Winter |

20-40% |

Excessive dryness |

Humidification |

Evaporative humidifier |

Summer Storage Strategies

Summer humidity often exceeds ideal humidity parameters in many regions. Increased moisture combined with higher temperatures creates perfect conditions for sugar bloom development. Run dehumidifiers continuously during humid months, monitor storage areas multiple times daily, and minimize door openings allowing humid outdoor air into controlled spaces.

Consider reducing storage inventory during summer months, producing smaller batches more frequently. Fresh chocolate requires less time in challenging storage conditions reducing bloom risk. This strategy particularly benefits operations lacking professional climate control equipment maintaining precise ideal humidity year-round.

Winter Challenges

Heated indoor spaces during winter often fall below ideal humidity minimums. Central heating dramatically reduces relative humidity creating excessively dry conditions. While preferable to excessive humidity, extreme dryness causes chocolate cracking and static electricity issues during handling and packaging.

Add moisture using evaporative humidifiers when winter humidity drops below 40%. Monitor carefully avoiding overcorrection into excessive humidity territory. Some operations find winter the easiest season for ideal humidity maintenance since dehumidification proves simpler than humidification in most climates.

Humidity During Chocolate Production

Tempering Room Conditions

Chocolate tempering requires precise environmental control including humidity management. The ideal humidity of 40-50% applies equally to tempering spaces where improper humidity disrupts crystallization patterns. High humidity causes surface condensation during cooling while excessive dryness creates static electricity interfering with chocolate handling.

Professional tempering operations use automated tempering equipment within climate-controlled rooms. Quality tempering machines produce perfectly tempered chocolate though environmental conditions still affect chocolate after exiting equipment. Maintain ideal humidity in tempering areas ensuring chocolate quality from tempering through cooling.

Molding and Enrobing Areas

Molding rooms require stringent ideal humidity control preventing moisture from contaminating mold surfaces before chocolate addition. Even slight moisture in polycarbonate molds from our chocolate molds collection causes chocolate to seize and develop bloom during setting. Ensure molds remain in controlled environment during warming and preparation, avoiding condensation formation.

Enrobing operations demand consistent ideal humidity throughout coating and cooling tunnels. Professional equipment incorporates environmental control maintaining optimal conditions from chocolate application through final crystallization.

Decorating and Finishing Spaces

Chocolate decoration areas require ideal humidity preventing moisture interference with cocoa butter colors and spray applications. Professional colors perform optimally when applied in controlled humidity environments. Excessive moisture causes colors to streak or develop bloom before chocolate coating adheres, while excessive dryness increases static electricity attracting dust to chocolate surfaces.

Spray finishing requires humidity control for proper atomization and application. Professional spray equipment maintains chocolate temperature but cannot compensate for environmental humidity problems. Maintain ideal humidity in spray booths ensuring professional results from sophisticated equipment investments.

Troubleshooting Humidity-Related Problems

Identifying Sugar Bloom

Sugar bloom appears as white, grainy coating distinguishable from fat bloom through texture and location. Sugar bloom feels rough and granular while fat bloom appears smooth and waxy. Sugar bloom typically develops on chocolate surfaces first exposed to moisture like outer edges and tops, while fat bloom distributes more evenly across all surfaces.

Test uncertain bloom by rubbing small area with gloved finger. Sugar bloom doesn't disappear with friction while fat bloom may temporarily reduce through surface cocoa butter melting. Sugar bloom indicates ideal humidity was exceeded either during storage or through condensation during temperature changes.

Preventing Condensation Damage

Condensation causes immediate sugar bloom development as moisture contacts chocolate surfaces. Prevent condensation when moving chocolate between temperature zones by allowing gradual temperature equilibration. Remove refrigerated chocolate in sealed containers, allowing containers to reach room temperature before opening. This prevents warm, humid air from contacting cold chocolate surfaces causing instant moisture condensation.

Professional operations use staged temperature zones moving chocolate through progressively warmer spaces rather than direct refrigerator-to-room-temperature transfer. While time-consuming, this approach prevents condensation damage to products representing significant production investment. Maintaining ideal humidity throughout all temperature zones eliminates most condensation risk.

Salvaging Compromised Chocolate

Chocolate showing sugar bloom from humidity exposure requires remelting and remolding. Professional melting equipment processes bloomed chocolate back into usable state though some quality loss occurs through additional heat exposure. Separate bloomed chocolate from premium inventory, using it for applications where appearance matters less than flavor.

Some professionals incorporate bloomed chocolate into ganache, baked goods, or hot chocolate products where bloom becomes irrelevant. This approach prevents waste while acknowledging that restoring original quality proves impossible once sugar bloom develops from ideal humidity violations. For more information, see our guide on how to avoid chocolate bloom.

Long-Term Storage Strategies

Chocolate Shelf Life by Type

|

Chocolate Type |

Ideal Humidity |

Optimal Temp |

Maximum Shelf Life |

Quality Indicators |

|

Dark Chocolate (70%+) |

40-50% |

60-65°F |

18-24 months |

Glossy, snaps cleanly |

|

Dark Chocolate (55-69%) |

40-50% |

60-65°F |

16-20 months |

Smooth appearance |

|

Milk Chocolate |

40-45% |

60-65°F |

12-16 months |

No white spots |

|

White Chocolate |

40-45% |

60-65°F |

8-12 months |

Ivory color maintained |

|

Filled Chocolates |

40-50% |

60-65°F |

4-8 weeks |

No leakage, firm centers |

|

Ruby Chocolate |

40-45% |

60-65°F |

10-14 months |

Pink color preserved |

Inventory Rotation Systems

First-in-first-out rotation ensures chocolate sells or uses before quality degradation from extended storage. Even under perfect ideal humidity conditions, chocolate quality gradually declines over months. Date all incoming chocolate and ingredients, storing newest items behind older inventory enforcing proper rotation.

Specialized Long-Term Solutions

Long-term storage of raw ingredients like cacao beans requires different ideal humidity approaches than finished chocolate. Beans tolerate slightly higher humidity preventing excessive moisture loss that diminishes weight and concentrates flavors undesirably. Store beans in breathable containers allowing minimal air exchange without exposing them to ambient humidity fluctuations.

Cocoa butter blocks and cocoa liquor wafers store exceptionally well under ideal humidity conditions, maintaining quality for years when protected from moisture, light, and excessive heat. These ingredients provide flexibility for operations experiencing seasonal production variations requiring ingredient stockpiling during slower periods.

Quality Control and Documentation

Monitoring Protocols

Establish daily humidity checking routines recording measurements in quality control logs. Multiple daily readings reveal patterns missed by single-point checks; humidity fluctuates throughout day as HVAC systems cycle and ambient conditions change. Digital data-logging hygrometers provide continuous records documenting ideal humidity compliance for quality assurance purposes.

Set alarm thresholds alerting staff when humidity deviates from acceptable ranges. Immediate notification enables rapid correction before extended exposure causes chocolate damage. Test alarm systems regularly ensuring reliable operation protecting valuable inventory.

Documentation Standards

Maintain detailed storage condition records documenting temperature, humidity, and any environmental control system adjustments. This documentation provides evidence of proper storage should quality questions arise with customers or during inspections. Records also reveal equipment maintenance needs; gradual humidity increases may indicate dehumidifier performance degradation requiring service before complete failure.

Link storage condition logs with batch numbers tracking which chocolate experienced what conditions. Should bloom or quality issues develop, documentation enables root cause analysis determining whether storage conditions, production problems, or ingredient quality caused defects. This traceability proves essential for continuous improvement programs refining ideal humidity protocols based on real performance data.

Conclusion

Maintaining the ideal humidity for storing chocolate between 40-50% relative humidity proves essential for preserving quality, preventing sugar bloom, and extending shelf life across all chocolate varieties and forms. Success requires understanding moisture interaction with chocolate's complex structure, implementing appropriate monitoring and control systems, and maintaining vigilance throughout storage periods. Whether storing finished molded chocolates, raw cacao beans, or professional chocolate-making ingredients, proper humidity control protects investments while ensuring consistent quality that meets both professional standards and customer expectations. Explore professional storage solutions, climate-controlled equipment, and premium fine chocolate products at Zucchero Canada to build comprehensive chocolate storage systems maintaining optimal conditions protecting valuable chocolate inventory year-round.

References

Beckett, S. T. (2023). The science of chocolate (3rd ed.). Royal Society Chemistry.

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). John Wiley & Sons.

KREA Swiss. (2024). Professional food equipment for chocolate production. https://kreaswiss.com/food-equipment

Pavoni Italia. (2024). Professional color collections and chocolate tools. https://pavonitalia.com/en/collections/professional-collezioni-colori-e-materie-prime

Talbot, G. (2024). Chocolate storage and shelf life optimization. In Science and Technology of Enrobed and Filled Chocolate. Woodhead Publishing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.