Essential facts about chocolate bloom prevention:

- Chocolate bloom appears as white or grayish discoloration on chocolate surfaces due to fat or sugar migration

- Fat bloom occurs from temperature fluctuations, while sugar bloom results from moisture exposure

- Proper storage at 60-68°F (15-20°C) with 50-55% humidity prevents most bloom issues

- Bloom doesn't make chocolate unsafe but significantly affects appearance and texture

- Professional tempering and controlled cooling are crucial for preventing fat bloom on chocolate

- Sugar bloom on chocolate can often be prevented by avoiding condensation and moisture

- Remelting and retempering can restore bloomed chocolate to usable condition

- Quality chocolate with proper cocoa butter content resists bloom better than compound alternatives

Discover premium chocolate products less prone to bloom issues at Zucchero Canada's Fine Chocolate Collection - your source for professional-grade confectionery supplies.

Every chocolate lover has experienced the disappointment of discovering their favorite treats covered in an unappealing white or grayish film. This phenomenon, known as chocolate bloom, represents one of the most common chocolate defects that affects both home storage and professional confectionery operations.

Understanding what is chocolate bloom and mastering how to prevent chocolate bloom can save money, preserve quality, and maintain the visual appeal that makes chocolate so irresistible. Whether you're a professional chocolatier, baker, or chocolate enthusiast, this comprehensive guide will equip you with the knowledge to keep your chocolate looking and tasting its best.

From the science behind why does chocolate turn white to practical chocolate storage tips that work in real-world conditions, we'll explore every aspect of bloom prevention and management. You'll discover professional techniques, learn to identify different types of bloom, and understand when bloomed chocolate can be salvaged versus when it should be discarded.

What is Chocolate Bloom?

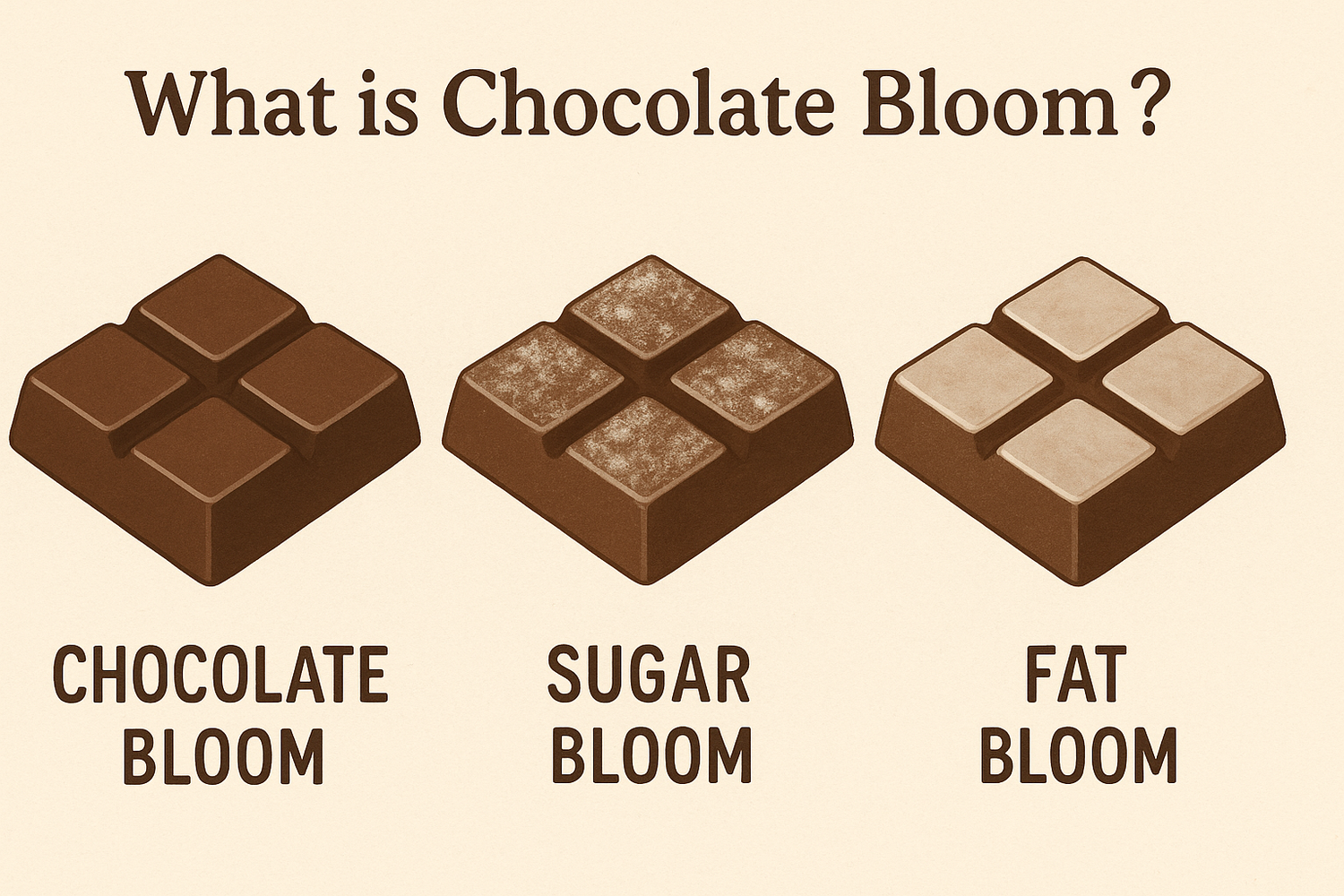

Chocolate bloom refers to the whitish or grayish discoloration that appears on chocolate surfaces, creating an unsightly film that makes even the finest chocolate look old or damaged. This visual defect occurs when certain components within the chocolate migrate to the surface, creating crystalline structures that scatter light differently than the smooth chocolate surface.

When chocolate is properly made and stored, its components remain in stable suspension, creating the smooth, glossy surface we associate with quality chocolate. Chocolate bloom occurs when this stability is disrupted, allowing fats or sugars to separate and migrate to the surface where they form visible crystalline deposits.

Not all chocolate bloom is created equal. Recognizing the difference between fat bloom on chocolate and sugar bloom on chocolate is crucial for both prevention and remediation strategies.

Fat Bloom

Fat bloom on chocolate appears as a whitish, sometimes slightly yellowish film that gives the chocolate surface a dull, cloudy appearance. This type of bloom occurs when cocoa butter or other fats in the chocolate migrate to the surface and recrystallize in an unstable form.

Characteristics of Fat Bloom:

- Develops gradually over days or weeks

- Creates a dull, matte finish on chocolate surfaces

- Often feels slightly soft or greasy to the touch

- More common in milk and white chocolates due to higher fat content

- Typically occurs due to temperature fluctuations during storage

I've observed in professional kitchens that fat bloom on chocolate often develops when chocolate is moved between environments with different temperatures - such as from a cool storage room to a warm kitchen and back again.

Sugar Bloom

Sugar bloom on chocolate results from moisture exposure and appears as a rougher, more crystalline white coating. This type of bloom occurs when water comes into contact with the chocolate surface, dissolving sugar which then recrystallizes as the moisture evaporates.

Characteristics of Sugar Bloom:

- Develops quickly, sometimes within hours of moisture exposure

- Creates a rough, gritty texture on the surface

- Often appears more intensely white than fat bloom

- Feels rough or sandy to the touch

- Can make chocolate taste slightly different due to altered sugar distribution

From my experience working with chocolate in humid climates, sugar bloom on chocolate is particularly problematic during summer months when condensation easily forms on cold chocolate surfaces.

Primary Causes of Chocolate Bloom

Understanding the root causes of chocolate bloom enables targeted prevention strategies. Most bloom issues stem from environmental factors that can be controlled with proper knowledge and preparation.

Temperature Fluctuations: The Leading Cause

Temperature instability ranks as the primary cause of fat bloom on chocolate. Even seemingly minor temperature changes can trigger fat migration if they occur repeatedly or involve significant variations.

Critical Temperature Scenarios:

- Moving chocolate between different storage environments

- Seasonal temperature changes in storage areas

- Inadequate climate control in retail or storage spaces

- Transportation in uncontrolled temperature conditions

In my experience managing chocolate inventory, I've found that even well-intentioned actions like moving chocolate from a cool basement to room temperature for use can trigger bloom if not done gradually.

Humidity and Moisture Exposure

High humidity creates conditions for sugar bloom on chocolate by introducing moisture that dissolves surface sugars. Even brief exposure to humid conditions can initiate this process.

Common Humidity-Related Issues:

- Condensation forming on cold chocolate surfaces in warm environments

- Storage in areas with poor ventilation or humidity control

- Exposure to steam from cooking or dishwashing activities

- Packaging that doesn't provide adequate moisture protection

Improper Storage Practices

Many chocolate defects including bloom result from storage mistakes that seem minor but have cumulative effects over time.

Storage-Related Bloom Triggers:

- Storing chocolate in locations with temperature variations

- Using inappropriate packaging that doesn't protect against environmental changes

- Placing chocolate near heat sources or in direct sunlight

- Failing to account for seasonal climate changes in storage areas

How to Prevent Chocolate Bloom

Mastering how to prevent chocolate bloom requires understanding both the science behind bloom formation and practical implementation of prevention strategies. Professional chocolatiers rely on precise environmental control and handling procedures to maintain chocolate quality.

Optimal Storage Conditions

The foundation of bloom prevention lies in maintaining consistent environmental conditions that keep chocolate components in stable suspension.

Ideal Storage Parameters:

- Temperature: 60-68°F (15-20°C) - avoid fluctuations greater than 2-3°F

- Humidity: 50-55% relative humidity maximum

- Air circulation: Gentle, consistent airflow without direct drafts

- Light protection: Store away from direct sunlight and fluorescent lighting

These parameters create an environment where chocolate remains stable without triggering the molecular migration that leads to bloom formation.

Frequently Asked Questions (FAQ)

What causes chocolate to develop white spots or coating?

Chocolate bloom causes white spots or coating through two mechanisms: fat bloom on chocolate occurs when temperature fluctuations cause cocoa butter to migrate to the surface, while sugar bloom on chocolate develops when moisture dissolves and recrystallizes surface sugars. Both create white discoloration but have different textures and prevention strategies.

Can you eat chocolate that has turned white?

Yes, bloomed chocolate remains safe to eat. Chocolate bloom doesn't indicate spoilage or contamination - it's purely a cosmetic and textural issue. However, sugar bloom on chocolate may create a gritty texture, and fat bloom on chocolate can affect the mouthfeel, making the eating experience less pleasant.

How long does it take for chocolate bloom to develop?

Fat bloom on chocolate typically develops over days to weeks of exposure to temperature fluctuations, while sugar bloom on chocolate can appear within hours of moisture exposure. The timeline depends on storage conditions, chocolate type, and severity of environmental stress.

What's the difference between sugar bloom and fat bloom?

Fat bloom on chocolate appears as a dull, whitish film caused by temperature changes and feels slightly soft or greasy. Sugar bloom on chocolate creates a rougher, more intensely white coating from moisture exposure and feels gritty or sandy. Fat bloom develops gradually, while sugar bloom can form quickly.

Can chocolate bloom be prevented completely?

How to prevent chocolate bloom effectively requires maintaining stable storage conditions: 60-68°F (15-20°C) temperature, 50-55% humidity, and protection from light. While complete prevention requires professional-level environmental control, following proper chocolate storage tips significantly reduces bloom risk in most situations.

Is bloomed chocolate safe to use for baking?

Bloomed chocolate works well for baking applications where appearance matters less than functionality. Remelting chocolate to remove bloom through the baking process often eliminates visual defects, and the taste impact is minimal in most recipes. However, assess the severity of bloom and any off-odors before use.

How do you fix chocolate that has turned white?

How to fix chocolate bloom depends on the severity and type. Minor fat bloom on chocolate can sometimes be removed by gentle buffing, while more extensive bloom requires remelting chocolate to remove bloom followed by proper tempering. Sugar bloom on chocolate is more difficult to remedy and often requires complete remelting.

Does expensive chocolate bloom less than cheap chocolate?

Higher-quality chocolate with proper cocoa butter content and professional tempering typically resists bloom better than compound chocolates or lower-grade products. Premium chocolate from suppliers like Zucchero Canada's Fine Chocolate Collection often demonstrates superior stability due to better ingredients and manufacturing processes.

What temperature should chocolate be stored at to prevent bloom?

Optimal storage temperature for preventing chocolate bloom is 60-68°F (15-20°C) with minimal fluctuation. Temperatures above 75°F (24°C) increase fat bloom on chocolate risk, while rapid temperature changes of even a few degrees can trigger bloom development in sensitive chocolate types.

Can humidity cause chocolate bloom?

Yes, high humidity is the primary cause of sugar bloom on chocolate. Moisture dissolves surface sugars which recrystallize as white deposits when the water evaporates. Maintaining storage humidity below 55% significantly reduces sugar bloom risk, while condensation from temperature changes poses the greatest moisture threat.

Conclusion

The distinction between fat bloom on chocolate and sugar bloom on chocolate helps target prevention efforts effectively. While fat bloom results from temperature instability, sugar bloom stems from moisture exposure, requiring different protective strategies for optimal results.

For those seeking reliable, bloom-resistant chocolate products, working with quality suppliers who understand proper tempering and storage makes a significant difference. Zucchero Canada offers professional-grade chocolate products that demonstrate superior stability when stored according to best practices.

Remember that while chocolate bloom affects appearance and texture, it doesn't indicate safety issues. Understanding when bloomed chocolate can be restored through remelting chocolate to remove bloom versus when replacement is necessary helps make economical decisions while maintaining quality standards.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.