In the chocolate manufacturing industry, the condition of your equipment directly impacts product quality, operational efficiency, and overall profitability. Properly maintained chocolate machinery not only produces superior products but also experiences fewer breakdowns, operates more efficiently, and has a significantly longer service life.

Whether you manage a small artisanal chocolate workshop or oversee a large-scale production facility, implementing systematic cleaning and maintenance protocols is essential for success. This comprehensive guide will walk you through everything you need to know about caring for your valuable chocolate processing equipment.

Types of Chocolate Equipment Requiring Regular Maintenance

Tempering Machines

Chocolate tempering machines are the heart of any chocolate production facility. These precision instruments control crystallization to ensure your chocolate has the perfect shine, snap, and texture. Regular maintenance prevents temperature fluctuation issues and extends the machine's operational life.

Enrobers and Coating Equipment

Chocolate enrobers apply consistent, even coatings to confections. The complex belt systems, pumps, and heating elements in these machines require specific maintenance procedures to prevent chocolate buildup and ensure uniform coating.

Chocolate Melters and Holding Tanks

These units keep chocolate at precise temperatures for extended periods. Proper maintenance prevents scorching, contamination, and temperature control problems that can ruin entire batches of product.

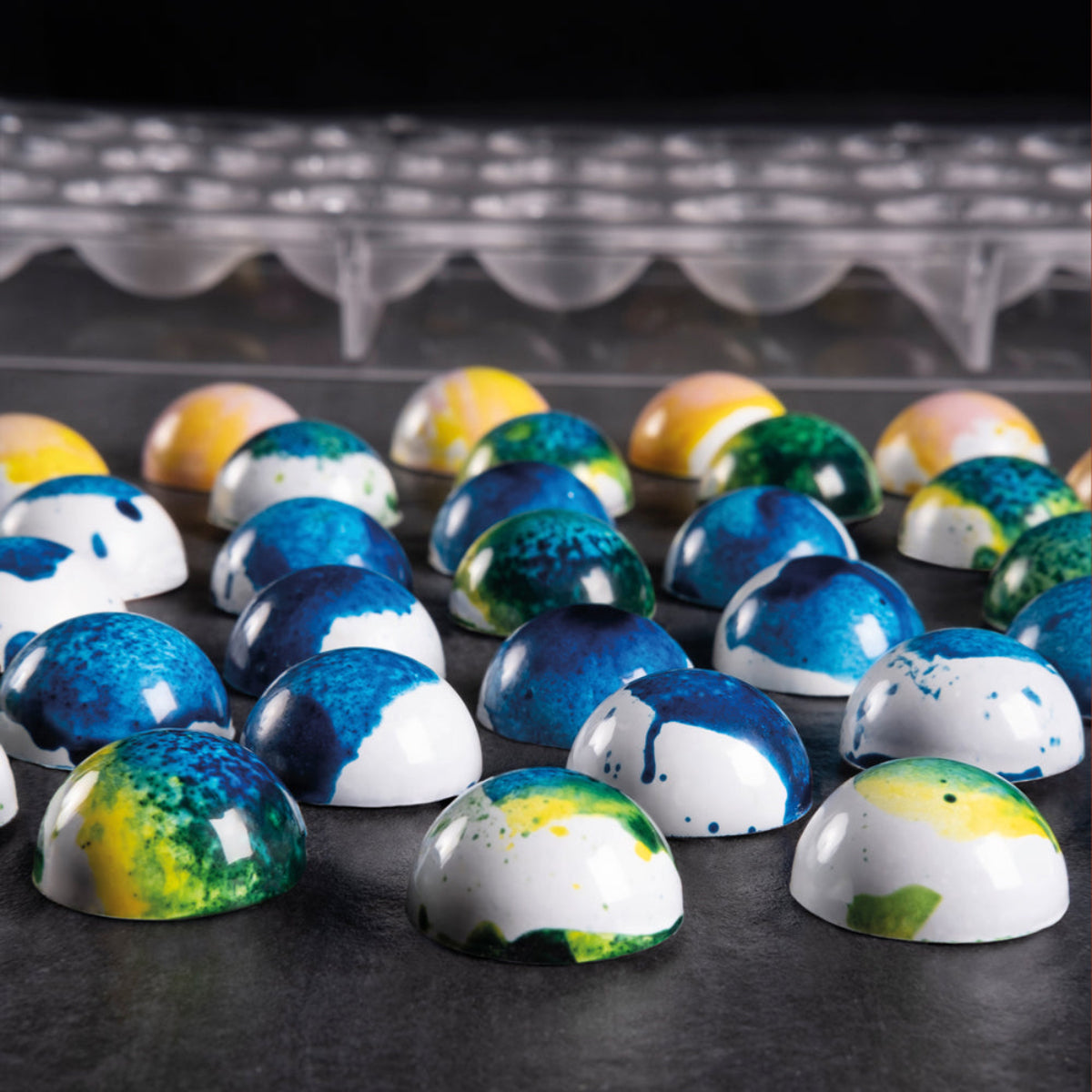

Molding Lines and Depositors

Automated molding equipment must be meticulously maintained to ensure precise depositing and consistent product weight. Even minor misalignments can lead to significant product waste and quality issues.

Cooling Tunnels

Cooling tunnels control the crystallization process in chocolate production. Their refrigeration systems, fans, and conveyor components require specialized maintenance to ensure optimal performance.

Why Maintaining and Cleaning Chocolate Equipment is Essential

Properly maintaining and cleaning chocolate equipment is absolutely critical for several important reasons that affect both your business operations and the end consumer. Let me explain the key reasons why this maintenance is non-negotiable:

Food Safety and Regulatory Compliance

First and foremost, chocolate equipment maintenance is about ensuring food safety. Chocolate processing equipment that isn't properly cleaned can become a breeding ground for harmful bacteria, mold, and other contaminants. Since chocolate products are consumed directly, any contamination can pose serious health risks to consumers.

Food safety regulations around the world (like FDA regulations in the US or FSMA requirements) mandate strict sanitation protocols for food processing equipment. Regular cleaning and maintenance isn't just good practice—it's legally required. Failing inspections can result in production shutdowns, recalls, fines, and even criminal charges in severe cases.

Product Quality and Consistency

Chocolate is remarkably sensitive to its processing environment. Even small amounts of residue or improperly maintained equipment can significantly impact the final product:

-

Old chocolate residue can become rancid and contaminate fresh batches, creating off-flavors or odors

-

Inconsistent temperature control from poorly maintained equipment leads to improper crystallization, resulting in chocolate that lacks shine, has poor snap, or develops bloom

-

Cross-contamination between different chocolate types (dark, milk, white) or flavored varieties can ruin entire batches

-

Residue buildup in molds affects the appearance and detail of finished products

In the competitive chocolate industry, consistency is everything—consumers expect the same high-quality experience with every purchase.

Equipment Efficiency and Longevity

Chocolate is a challenging substance to work with from a mechanical perspective. The combination of sugar crystals, cocoa butter, and other ingredients creates a mixture that can be quite abrasive and difficult to process. Additionally:

-

Cocoa butter solidifies at room temperature, creating hardened deposits that can jam moving parts

-

Sugar crystallization creates abrasive surfaces that accelerate wear on components

-

Deposits build up gradually, reducing the efficiency of heat transfer surfaces

-

Moving parts with chocolate buildup require more energy to operate, increasing power consumption

Regular maintenance prevents these issues, extending equipment life sometimes by 5-10 years compared to poorly maintained machines.

Worker Safety Considerations

Properly maintained equipment is safer equipment:

-

Chocolate buildup can jam moving parts, creating unexpected machine behavior

-

Employees attempting to clear jams in unmaintained equipment face greater injury risks

-

Improperly maintained electrical components present shock or fire hazards

-

Cleaning overly soiled equipment often requires harsher chemicals and more difficult procedures

When equipment is regularly maintained, it operates more predictably and safely.

Daily Cleaning Procedures for Chocolate Equipment

Pre-Cleaning Preparation

Before beginning any cleaning procedure:

-

Power down all equipment following manufacturer safety protocols

-

Allow hot surfaces to cool to safe temperatures

-

Disassemble removable parts according to manufacturer guidelines

-

Prepare appropriate cleaning solutions and tools

Removing Chocolate Residue

Chocolate residue must be thoroughly removed to prevent contamination and maintain product quality:

-

Scrape excess chocolate from surfaces using food-grade plastic scrapers

-

Remove and clean all detachable parts in designated washing areas

-

Use warm water (100-110°F/38-43°C) for initial rinse to prevent chocolate from hardening further

-

Apply food-grade detergents specifically formulated for chocolate processing equipment

Sanitization Process

After removing all visible chocolate:

-

Apply food-safe sanitizing solution following concentration guidelines

-

Ensure all food-contact surfaces receive appropriate contact time with sanitizer

-

Rinse thoroughly with clean, potable water if required by sanitizer instructions

-

Allow equipment to air dry completely before reassembly

Special Considerations for Different Equipment Types

Different machines have unique cleaning requirements:

-

Tempering machines: Clean scraper blades thoroughly and inspect for damage

-

Enrobers: Pay special attention to belt cleaning and tensioning system

-

Molds: Inspect for chocolate buildup in fine details and corners

-

Pumps and pipes: Use appropriate brushes to clean internal components

Weekly Maintenance Tasks

Mechanical Components Inspection

Weekly inspections should include:

-

Checking belt tension and alignment on conveyors

-

Inspecting drive chains for proper lubrication

-

Examining gears for wear or damage

-

Testing safety switches and emergency stop functionality

Lubrication Requirements

Proper lubrication is essential:

-

Only use food-grade lubricants approved for chocolate production

-

Follow manufacturer guidelines for lubrication points and frequency

-

Prevent over-lubrication which can contaminate products

-

Document all lubrication activities in maintenance logs

Calibration Checks

Regular calibration ensures product consistency:

-

Verify temperature sensors against calibrated thermometers

-

Check weight accuracy on depositors and portion control systems

-

Test humidity controls in cooling tunnels

-

Calibrate speed controls on conveyors and mixers

Monthly and Quarterly Maintenance Procedures

Deep Cleaning Protocols

Scheduled deep cleaning should include:

-

Disassembling equipment more thoroughly than daily cleaning permits

-

Cleaning areas not accessible during regular maintenance

-

Descaling water-heated components

-

Steam cleaning where appropriate and manufacturer-approved

Preventative Maintenance Tasks

Preventative maintenance prevents costly breakdowns:

-

Replacing worn seals and gaskets

-

Checking electrical connections for signs of wear or corrosion

-

Inspecting motors for unusual noise or excessive heat

-

Examining refrigeration systems for optimal performance

Professional Service Requirements

Some maintenance tasks require specialized expertise:

-

Schedule manufacturer-recommended service intervals

-

Have certified technicians perform complex repairs and adjustments

-

Update software and control systems when available

-

Document all professional service for warranty and compliance purposes

Conclusion: Creating a Culture of Equipment Care

Implementing successful maintenance programs requires organizational commitment:

-

Promote understanding of how equipment care impacts product quality

-

Recognize and reward staff who excel at maintenance procedures

-

Continuously improve processes based on experience and results

-

Invest in training and proper tools for maintenance staff

By following these comprehensive guidelines for maintaining and cleaning chocolate equipment, manufacturers can ensure consistent product quality, maximize operational efficiency, and extend the life of their valuable machinery investments.

FAQs About Chocolate Equipment Maintenance

How often should chocolate tempering machines be deep cleaned?

Most manufacturers recommend weekly deep cleaning for tempering machines, with daily cleaning of all product-contact surfaces. However, production volume and types of chocolate processed may require adjusting this frequency.

What temperature water should be used when cleaning chocolate equipment?

Use warm water (100-110°F/38-43°C) for initial cleaning, as this helps dissolve cocoa butter without causing it to harden further. Avoid very hot water which can "cook" milk proteins onto surfaces.

Can regular cleaning products be used on chocolate equipment?

No, only food-grade cleaning products specifically formulated for food processing equipment should be used. Regular cleaning products may contain fragrances or chemicals that can contaminate chocolate.

How do I know if my chocolate equipment needs professional service?

Consider professional service if you notice inconsistent temperature control, unusual noises, decreased production efficiency, or product quality issues that persist despite routine maintenance.

What documentation should we maintain for our chocolate equipment maintenance?

Maintain detailed logs of all cleaning procedures, maintenance activities, part replacements, calibrations, and professional services. These records are essential for food safety compliance, warranty validation, and troubleshooting.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.