Chocolate molds represent a significant investment for any chocolate maker, whether you're a home enthusiast or a professional chocolatier. High-quality molds from brands like Chocolate World, Pavoni Italia, or Martellato can last for years—even decades—when properly maintained. However, improper handling, cleaning, or storage can quickly damage these precision tools, compromising both the quality of your chocolates and your bottom line.

This comprehensive guide covers everything you need to know about caring for chocolate molds across different materials, addressing common problems, and implementing professional maintenance routines that extend their usable life. By following these expert recommendations, you'll protect your investment while consistently creating flawless chocolate creations.

Understanding Your Chocolate Molds

Types of Chocolate Molds and Their Properties

Polycarbonate Molds

Polycarbonate molds are the gold standard for professional chocolate making. These rigid, transparent molds create chocolates with exceptional shine and snap, featuring precise details that distinguish premium confections.

Key characteristics:

-

Durable but can scratch or cloud with improper care

-

Heat-resistant up to approximately 180°F (82°C)

-

Relatively rigid and inflexible

-

Premium options from manufacturers like Chocolate World Belgium, Martellato, and Pavoni Italia

Silicone Molds

Silicone molds offer flexibility and ease of use, making them popular for both professional and home chocolate makers. Their inherent flexibility allows for easy removal of delicate chocolate pieces.

Key characteristics:

-

Highly flexible material

-

Temperature resistant from -40°F to 446°F (-40°C to 230°C)

-

Less likely to break or crack than rigid molds

-

Popular brands include Pavoni Italia, Silikomart, and Martellato

PET Plastic Molds

PET (polyethylene terephthalate) molds are more affordable alternatives to polycarbonate, making them popular for home use and beginner chocolatiers.

Key characteristics:

-

Less durable than polycarbonate but more economical

-

Lower heat resistance (avoid hot water cleaning)

-

Typically less detailed than premium polycarbonate molds

-

Good for occasional or beginner use

Metal Molds

Traditional metal molds (often stainless steel or tin) remain popular for certain applications, particularly in historic chocolate making techniques.

Key characteristics:

-

Excellent heat conductivity

-

Extremely durable when properly maintained

-

Require different handling than plastic or silicone molds

-

Often used for traditional chocolate styles

Essential Cleaning Practices

Proper cleaning is perhaps the most critical aspect of mold maintenance. Different mold materials require specific approaches to cleaning to prevent damage while ensuring hygienic conditions.

Cleaning Polycarbonate Molds

Polycarbonate molds require gentle cleaning to prevent scratching, clouding, or other damage that affects chocolate release and appearance.

Recommended cleaning process:

-

Timing is crucial: Clean molds soon after use, but allow chocolates to fully set and contract before removing them.

-

Initial chocolate removal: Turn the mold upside down and gently flex it or tap it on a clean surface covered with parchment paper. Most chocolate should release easily if properly tempered.

-

Avoid water initially: Do not immediately rinse with water. Instead, use a soft, lint-free cloth to wipe away any remaining chocolate residue.

-

Temperature considerations: Never expose polycarbonate molds to extreme temperature changes. Allow them to reach room temperature before cleaning.

-

When necessary, use warm (not hot) water: If chocolate residue remains, use lukewarm water (80-90°F/27-32°C) without soap initially.

-

Gentle soap only when required: If oil or fat residue persists, use a minimal amount of mild, fragrance-free dish soap.

-

Never use abrasives: Avoid scouring pads, brushes with stiff bristles, or abrasive cleaners that can permanently scratch the surface.

-

Drying completely: Air dry the molds in a dust-free environment or gently pat dry with a microfiber cloth. Ensure they are completely dry before storage.

Cleaning Silicone Molds

Silicone molds benefit from their flexibility and non-stick properties but require specific care to maintain these qualities.

Recommended cleaning process:

-

Remove chocolate first: Gently flex the mold to release chocolate pieces before any cleaning.

-

Warm water rinse: Use warm (not hot) water to rinse away any loose chocolate particles.

-

Gentle soap cleaning: Unlike polycarbonate, silicone can handle mild dish soap more readily. Use a small amount with warm water.

-

For stubborn residue: Soak in warm, soapy water for up to 30 minutes – no longer, as prolonged soaking can affect the material.

-

Avoid dishwashers: While some manufacturers claim dishwasher safety, the harsh detergents and high heat can degrade silicone over time.

-

Thorough drying: Air dry completely before storage to prevent mold or mildew development.

-

Removing odors: If silicone molds develop odors, a paste of baking soda and water can help neutralize them without damaging the material.

Cleaning PET Plastic Molds

PET molds require gentler treatment than their polycarbonate counterparts due to lower heat resistance and durability.

Recommended cleaning process:

-

Cool water only: Use cool to lukewarm water, never hot, as PET has lower heat resistance.

-

Minimal soap: Use very little mild soap if necessary.

-

Quick cleaning: Don't soak PET molds for extended periods.

-

Gentle drying: Pat dry with a soft cloth rather than air drying to prevent water spots.

Cleaning Metal Molds

Metal molds have different requirements due to potential oxidation or corrosion concerns.

Recommended cleaning process:

-

Warm water cleaning: Use warm water with mild soap.

-

Prevent oxidation: Dry immediately and thoroughly to prevent water spots or oxidation.

-

For tin molds: Consider a light coating of neutral vegetable oil after cleaning to prevent oxidation.

-

Avoid acidic cleaners: These can damage metal surfaces.

Professional Storage Techniques

Proper storage is essential for maintaining mold quality between uses, preventing damage, contamination, or warping.

Temperature and Environment Control

-

Ideal storage temperature: Store molds at stable room temperature (65-75°F/18-24°C).

-

Avoid direct sunlight: UV exposure can degrade plastic molds over time, causing yellowing or brittleness.

-

Control humidity: Excessive humidity can promote mold growth or cause metal molds to oxidize. Aim for 30-50% relative humidity.

-

Avoid strong odors: Store away from strong-smelling ingredients, as many mold materials can absorb odors that transfer to chocolate.

Physical Protection Methods

-

Individual wrapping: Wrap each mold in acid-free tissue paper or microfiber cloths to prevent scratching.

-

Stack with protection: If stacking is necessary, place parchment paper or plastic sheets between molds.

-

Dedicated storage containers: Use plastic storage bins with lids to protect from dust and contamination.

-

Vertical storage options: When possible, store polycarbonate molds vertically in specialized racks or modified file organizers to prevent warping and save space.

-

Original packaging: Many premium molds come with custom packaging designed specifically for proper storage – these are often the best option.

Handling Best Practices

How you handle molds during production significantly impacts their longevity. These professional handling techniques help prevent damage during daily use.

Clean Hands Protocol

-

Wash hands thoroughly: Always work with clean, dry hands when handling molds.

-

Avoid lotions or oils: Hand creams or oils can transfer to molds and affect chocolate release.

-

Consider food-safe gloves: Cotton or nitrile gloves can prevent fingerprints and oil transfer.

Temperature Management

-

Never freeze molds: Extreme cold can make plastic molds brittle and prone to cracking.

-

Pre-warming considerations: If pre-warming molds, never exceed 90°F (32°C) for polycarbonate or PET molds.

-

Cooling time: Allow molds to cool naturally after use before cleaning or storing.

-

Avoid refrigerator condensation: If refrigerating filled molds, be aware of condensation when removing them, which can affect chocolate quality.

Physical Handling

-

Support the base: Always support polycarbonate molds from underneath when moving them, especially when filled with liquid chocolate.

-

Avoid twisting: Never twist or torque rigid molds, which can cause stress fractures over time.

-

Gentle pressure: When removing chocolates, apply even, gentle pressure rather than excessive force.

Troubleshooting Common Issues

Even with proper care, chocolate molds can develop issues over time. Here's how to address common problems and potentially restore damaged molds.

Clouding or Hazing in Polycarbonate

Cloudy polycarbonate molds produce chocolates with diminished shine. This typically results from:

-

Micro-scratches from abrasive cleaning

-

Mineral deposits from hard water

-

Residual oils or fats

Restoration techniques:

-

Mineral deposit removal: Soak in a solution of 1 part white vinegar to 3 parts distilled water for 30 minutes, then rinse thoroughly with distilled water.

-

Polish with microfiber: For light scratches, gently polish with a high-quality microfiber cloth.

-

Professional polishing: For valuable molds with significant clouding, professional polishing services are available through some chocolate equipment suppliers.

Sticky Silicone Molds

Silicone molds that become sticky or tacky have often absorbed oils over time.

Restoration techniques:

-

Baking soda paste: Create a paste with baking soda and water, apply to the mold surface, let sit for 1-2 hours, then rinse thoroughly.

-

Cornstarch application: Dust with cornstarch, let sit overnight, then rinse thoroughly.

-

Silicone rejuvenator: Commercial silicone rejuvenating products can restore proper surface properties.

Warped Molds

Warping typically occurs from improper storage or exposure to excessive heat.

Prevention and solutions:

-

Store flat or vertical: Ensure proper support during storage.

-

For minor warping: Sometimes gentle heat (no higher than 100°F/38°C) can help reshape a slightly warped mold when combined with proper weighting during cooling.

-

Serious warping: Unfortunately, severely warped molds often need replacement, as they will produce inconsistent chocolates.

Chocolate Sticking Issues

When properly maintained molds suddenly start having release problems:

-

Check tempering: Often the issue is with chocolate tempering rather than the mold itself.

-

Assess cleaning routine: Residual soap can cause sticking issues.

-

Consider temperature: Mold temperature can significantly affect release. Room temperature molds (68-72°F/20-22°C) typically perform best.

-

For polycarbonate: A very light conditioning with cocoa butter using a lint-free cloth can restore release properties.

Professional Maintenance Schedule

Professional chocolatiers implement regular maintenance schedules to extend mold life and ensure consistent quality.

Daily Maintenance

-

Clean properly after each use

-

Inspect for any damage or residue

-

Store appropriately

Weekly Maintenance

-

Deep cleaning of frequently used molds

-

Thorough inspection for any developing issues

-

Reorganization of storage to prevent pressure damage

Monthly Maintenance

-

Conditioning treatment for heavily used molds

-

Rotation of mold inventory to prevent excessive wear on favorites

-

Comprehensive inspection of storage conditions

Seasonal Maintenance

-

Complete inventory assessment

-

Professional restoration of valuable molds showing wear

-

Update storage systems if needed

Extending Your Mold Investment

Beyond basic care, these professional techniques can significantly extend the useful life of premium chocolate molds.

Rotation Strategy

Professional chocolatiers often purchase duplicate molds for popular designs and rotate their use, allowing each mold time to "rest" between production cycles.

Dedicated Usage Categories

Consider designating specific molds for particular chocolate types:

-

Dark chocolate only molds

-

Milk/white chocolate only molds

-

Colored cocoa butter molds

This prevents potential cross-contamination and minimizes cleaning requirements.

Professional Restoration Services

For valuable or rare molds showing significant wear, professional restoration services are available through specialty suppliers. These can include:

-

Professional polishing for polycarbonate

-

Specialized cleaning treatments

-

Minor repair of damaged details

When to Retire a Mold

Knowing when to retire a mold is also important for maintaining quality standards:

-

When fine details become impossible to clean properly

-

When release issues persist despite proper chocolate tempering

-

When structural integrity is compromised

-

When clouding or scratching significantly affects chocolate appearance

Brand-Specific Care Recommendations

Different manufacturers may have specific care recommendations for their products. Here are guidelines for some of the most popular premium brands:

Chocolate World Belgium

These premium polycarbonate molds benefit from:

-

Extra gentle handling due to their fine detail work

-

Storage in original packaging whenever possible

-

Avoiding any cleaning agents not explicitly approved by the manufacturer

Pavoni Italia

For both silicone and polycarbonate Pavoni molds:

-

Pay special attention to intricate designs that can trap chocolate

-

Store silicone molds flat rather than folded

-

Follow the manufacturer's specific temperature guidelines

Martellato

Martellato polycarbonate molds typically feature:

-

Specific recommendations against dishwasher use

-

Guidelines for compatible cleaning products

-

Recommended storage in their original blue packaging boxes

Silikomart

For their premium silicone molds:

-

Special care instructions for platinum silicone products

-

Specific temperature thresholds for various product lines

-

Recommendations against using cooking sprays or oils

Premium Chocolate Molds: The Zucchero Canada Collection

For Canadian chocolatiers and pastry professionals, Zucchero Canada offers an extensive collection of premium chocolate molds from Europe's most respected manufacturers. Their curated selection provides access to professional-grade molds while their expertise can help guide proper care practices.

Featured Collections and Care Considerations

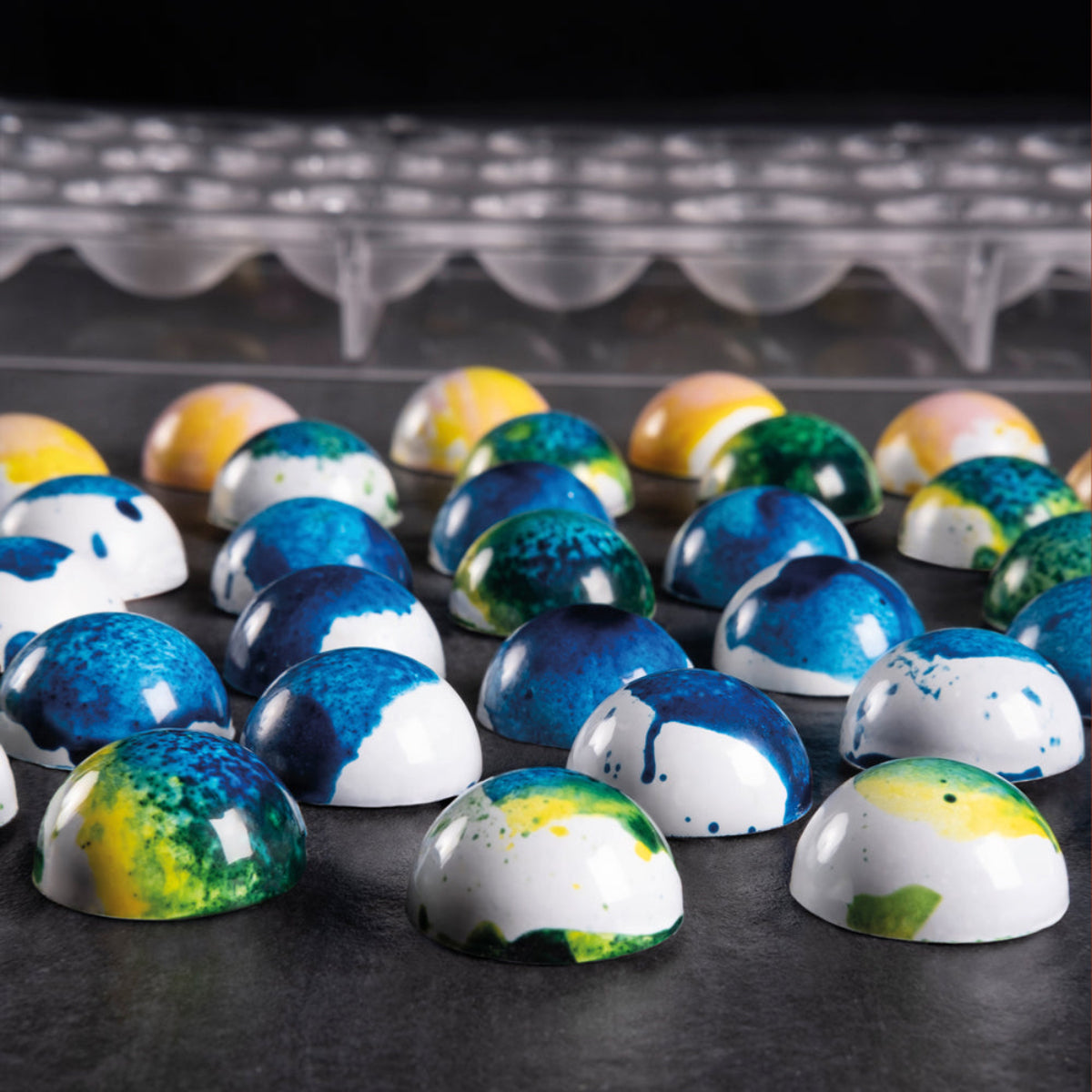

Polycarbonate Chocolate Molds

Zucchero Canada's polycarbonate mold collection includes premium options from Chocolate World Belgium and other European manufacturers. These high-gloss, rigid molds are engineered for flawless demolding and professional results:

-

Care considerations: The premium polycarbonate molds in this collection require the meticulous cleaning approaches outlined in our polycarbonate cleaning section. Their exceptional detail work and precision manufacturing justify investing extra time in proper maintenance.

-

Longevity factors: Many of these molds are rated for 10,000+ production cycles when properly maintained, making them true professional investments.

-

Storage recommendations: Store these premium molds in their original packaging when possible, or implement the vertical storage techniques described earlier for optimal results.

Thermoformed Chocolate Molds

Specialized thermoformed molds, like those for hot chocolate bombs and half-sphere systems, require specific care approaches:

-

Temperature sensitivity: These molds may have different temperature thresholds than standard polycarbonate. Follow manufacturer guidelines carefully.

-

Cleaning adaptations: The deeper cavities in many thermoformed designs require extra attention to cleaning corners and edges where chocolate can accumulate.

-

Storage considerations: Stacking these molds improperly can lead to warping or distortion. Use the horizontal storage techniques with proper separation materials described in our storage section.

3D & Seasonal Chocolate Molds

These intricate molds create stunning three-dimensional chocolate pieces but require specialized care:

-

Detail preservation: The fine details in these molds are particularly vulnerable to scratching or damage. Implement the microfiber cloth cleaning techniques we discussed for optimal preservation.

-

Thorough drying: The complex geometries of 3D molds can trap moisture, leading to water spots or mold growth. Ensure complete drying before storage.

-

Rotation strategy: Consider implementing our rotation strategy for these seasonal molds to extend their lifespan across multiple years of use.

Magnetic Chocolate Molds

Zucchero Canada's selection includes innovative magnetic systems that create seamless, professional chocolate pieces:

-

Component care: These systems often feature multiple components that must be cleaned and stored separately.

-

Magnet maintenance: Keep magnetic surfaces clean and free from chocolate debris to maintain proper sealing.

-

Assembly/disassembly: Follow proper techniques for assembling and disassembling to prevent damage to alignment mechanisms.

Professional Support for Mold Maintenance

Beyond their product offerings, Zucchero Canada provides valuable resources for chocolate mold care:

-

Technical guidance on extending mold lifespan

-

Recommendations for cleaning products compatible with specific mold types

-

Access to replacement parts for certain mold systems when components wear out

By combining the care techniques outlined in this guide with the premium quality molds available through Zucchero Canada's chocolate mold collection, chocolatiers can achieve professional results while maximizing their equipment investment.

Conclusion: The Value of Proper Mold Care

Investing time in proper chocolate mold care yields significant returns through:

-

Extended mold lifespan: Properly maintained molds can last for decades rather than months or years.

-

Consistent quality: Well-maintained molds produce chocolates with reliable shine, detail, and release properties.

-

Better efficiency: Molds in prime condition require less time for chocolate release and cleaning.

-

Cost savings: Replacing premium chocolate molds represents a significant expense that proper maintenance minimizes.

-

Professional results: The difference between amateur and professional chocolate often comes down to the condition of the molds used.

By implementing the care routines outlined in this guide, you'll protect your chocolate mold investment while consistently producing exceptional quality chocolates. Remember that each mold represents not just its purchase cost, but the potential for creating thousands of perfect chocolate pieces over its lifetime.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.