Achieving perfectly tempered chocolate requires precision and consistency. While experienced chocolatiers can often rely on visual cues and traditional testing methods, specialized measurement tools provide objective data that can significantly improve results. This comprehensive guide explores the various tools available for measuring chocolate temper accuracy, from beginner-friendly options to professional-grade equipment.

Understanding Chocolate Temper and Why Measurement Matters

Before diving into measurement tools, it's important to understand what proper temper means. Tempered chocolate contains stable Form V crystals that give confections their desirable characteristics:

-

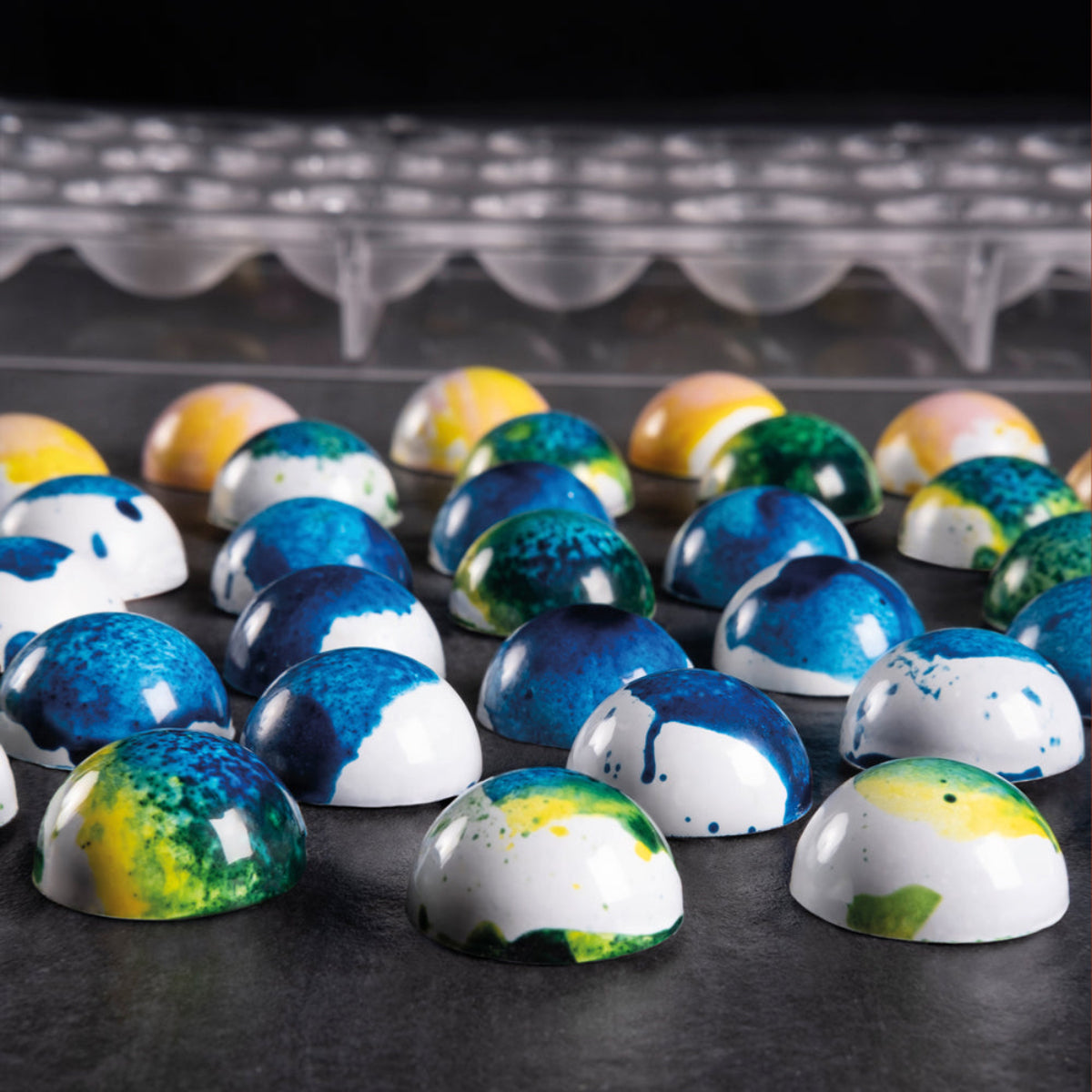

Glossy appearance

-

Clean snap

-

Smooth mouthfeel

-

Resistance to bloom

-

Proper contraction for easy demolding

Precise temperature control is essential throughout the tempering process. Even slight variations can lead to improper crystallization, making accurate measurement tools invaluable for consistent results.

Digital Thermometers: The Foundation of Temper Measurement

The most fundamental and accessible temper measurement tool is the digital thermometer. However, not all thermometers are equally suitable for chocolate work.

Instant-Read Digital Thermometers

How They Work: These thermometers provide quick temperature readings through a metal probe inserted into chocolate.

Features to Look For:

-

Temperature range of 32-130°F (0-55°C)

-

Accuracy of ±0.5°F (±0.3°C) or better

-

Fast response time (under 6 seconds)

-

Thin probe tip (under 3mm) to minimize chocolate displacement

-

Waterproof design for easy cleaning

-

Calibration capability

Recommended Models:

-

Thermapen Mk4 or ONE

-

Lavatools Javelin PRO

-

Taylor Precision Products Digital Thermometer

Advantages:

-

Versatile for multiple kitchen applications

-

Relatively affordable ($15-$100 depending on quality)

-

Simple to use with minimal training

Limitations:

-

Only measures temperature, not crystallization quality

-

Requires constant monitoring for temperature changes

-

Potential for contamination between readings

Infrared Thermometers

How They Work: These non-contact thermometers measure surface temperature by detecting infrared energy emitted from chocolate.

Features to Look For:

-

Adjustable emissivity (chocolate has an emissivity of approximately 0.95)

-

Distance-to-spot ratio of at least 12:1

-

Temperature range covering 70-120°F (20-50°C)

-

LCD display with backlight for easy reading

Advantages:

-

Non-contact measurement prevents contamination

-

Instant readings without disrupting the chocolate

-

Allows for scanning multiple areas quickly

Limitations:

-

Only measures surface temperature

-

Accuracy can be affected by ambient conditions

-

May not accurately reflect internal temperature of chocolate mass

Specialized Chocolate Tempering Measurement Tools

Beyond basic temperature measurement, specialized tools can provide more comprehensive data about chocolate's crystallization status.

Chocolate Temper Meters

How They Work: These dedicated devices measure both temperature and crystallization by analyzing cooling curves and solidification patterns.

Notable Examples:

-

Tricor Temper Index Meter

-

Chocometer by Sollich

-

ChocoVision Crystal Meter

Measurement Process:

-

A small sample of melted chocolate is placed in the device

-

The sample is cooled at a controlled rate

-

The solidification pattern is monitored and analyzed

-

A numerical value or index indicating temper quality is displayed

Advantages:

-

Provides objective measurement of crystallization quality

-

Eliminates guesswork and subjective assessment

-

Allows for standardization across production batches

Limitations:

-

Expensive ($500-$5,000+) and primarily designed for commercial use

-

Requires training to properly interpret results

-

Consumes small amounts of chocolate for each test

Viscometers for Chocolate

How They Work: These instruments measure the viscosity (flow resistance) of liquid chocolate, which correlates with crystal formation and temper quality.

Types Available:

-

Rotational viscometers

-

Falling ball viscometers

-

Capillary viscometers

Applications:

-

Measuring changes in viscosity during the tempering process

-

Detecting proper crystal formation by observing flow behavior

-

Ensuring consistency between batches

Advantages:

-

Provides quantitative data beyond temperature alone

-

Can detect subtle changes in chocolate's physical properties

-

Useful for production environments requiring standardization

Limitations:

-

Specialized equipment with significant cost ($1,000-$10,000)

-

Requires technical knowledge to operate and interpret

-

May need calibration specific to chocolate types

DIY and Accessible Temper Testing Methods

For home chocolatiers and small-scale producers, several affordable alternatives provide useful information about temper quality.

Temper Test Strips

How They Work: Pre-made plastic or metal strips of standardized size that are dipped in chocolate and observed as it sets.

Testing Process:

-

Dip the strip in tempered chocolate

-

Hold vertically to allow excess to drain

-

Observe setting time, pattern, and appearance

-

Compare against reference standards

Advantages:

-

Affordable ($5-$20 for reusable strips)

-

Standardized testing surface

-

Visual feedback on setting quality

Limitations:

-

Somewhat subjective interpretation

-

Requires experience to recognize proper setting patterns

-

Less precise than electronic measurement

Cooling Curve Test Kits

How They Work: Simple kits that include temperature probes and timers to monitor how quickly chocolate cools and solidifies.

Testing Process:

-

Place a measured amount of chocolate in a provided container

-

Insert temperature probe

-

Record temperature readings at timed intervals

-

Plot the cooling curve and analyze against reference curves

Advantages:

-

More affordable than professional tempering meters ($50-$150)

-

Provides quantifiable data beyond visual inspection

-

Helps develop understanding of chocolate crystallization behavior

Limitations:

-

More time-consuming than instant measurement tools

-

Requires careful environmental control

-

Some interpretation skill needed

Interpreting Temper Measurements

Having the right tools is only useful if you understand how to interpret the readings they provide.

Temperature Ranges for Properly Tempered Chocolate

|

Chocolate Type |

Working Temperature Range |

|

Dark Chocolate |

88-90°F (31-32°C) |

|

Milk Chocolate |

86-88°F (30-31°C) |

|

White Chocolate |

84-86°F (29-30°C) |

Beyond Temperature: Crystal Formation Indicators

Proper temper involves more than just reaching the correct temperature. Quality indicators include:

-

Setting Time: Properly tempered chocolate begins to set within 3-5 minutes at room temperature

-

Contraction: Well-tempered chocolate contracts slightly as it cools

-

Surface Appearance: Formation of a uniform, glossy surface without streaking

-

Snap Quality: Clean, crisp break when fully set

-

Bloom Resistance: Stability when exposed to moderate temperature fluctuations

Integrated Systems: Tempering Machines with Built-in Measurement

Modern chocolate tempering machines often incorporate sophisticated measurement tools directly into their operation.

Features of Advanced Tempering Systems

Temperature Control Systems:

-

Multi-point temperature monitoring

-

PID controllers for precise temperature maintenance

-

Temperature gradient detection across the chocolate mass

Crystallization Monitoring:

-

Viscosity sensors to detect changes during crystallization

-

Automated cooling curve analysis

-

Seed crystal detection systems

Feedback Mechanisms:

-

Real-time adjustments based on measurement data

-

Alert systems for out-of-range conditions

-

Data logging for quality control and process improvement

Examples of Integrated Systems:

-

Selmi Temper machines with TempSensor technology

-

ChocoVision Revolation series with Crystal sensing

-

FBM Tempering lines with EasyTemp measurement

Calibration and Maintenance of Chocolate Temper Tools

Maintaining accuracy in your measurement tools is crucial for consistent results.

Calibration Techniques

Digital Thermometer Calibration:

-

Prepare an ice bath (32°F/0°C reference point)

-

Insert thermometer probe without touching container sides

-

Adjust calibration according to manufacturer instructions

-

Repeat with boiling water (212°F/100°C at sea level) if the thermometer offers dual-point calibration

Tempering Meter Calibration:

-

Use manufacturer-provided reference samples

-

Run calibration cycles according to equipment instructions

-

Document calibration data for quality assurance

-

Schedule regular calibration checks based on usage frequency

Maintenance Best Practices

-

Clean all tools thoroughly after each use to prevent chocolate buildup

-

Store electronic tools away from heat, moisture, and direct sunlight

-

Replace batteries in digital devices regularly

-

Check for damage to probes, sensors, or connection points

-

Keep calibration records to track potential drift over time

Comparative Analysis: Choosing the Right Tool for Your Needs

|

Tool Type |

Cost Range |

Accuracy Level |

Best For |

Learning Curve |

|

Digital Thermometer |

$15-100 |

Good |

Beginners, home use |

Low |

|

Infrared Thermometer |

$30-150 |

Moderate |

Quick checks, production monitoring |

Low |

|

Temper Meter |

$500-5,000+ |

Excellent |

Professional production, research |

High |

|

Viscometer |

$1,000-10,000+ |

Excellent |

Commercial production, formulation |

Very High |

|

Test Strips |

$5-20 |

Fair |

Beginners, supplementary testing |

Moderate |

|

Cooling Curve Kits |

$50-150 |

Good |

Small businesses, educational use |

Moderate |

|

Integrated Systems |

$2,000-20,000+ |

Excellent |

Production environments |

High |

FAQ: Common Questions About Chocolate Temper Measurement

How often should I check chocolate temperature during tempering?

For manual tempering, check the temperature at least every 2-3 minutes during critical phase transitions. During working with tempered chocolate, check every 5-10 minutes to ensure it remains in the working range.

Can I use a standard meat thermometer for chocolate?

While possible, standard meat thermometers are generally not recommended as they typically have thicker probes that displace more chocolate, slower response times, and less precision in the critical tempering temperature range.

Do different chocolate brands require different measurement approaches?

Yes. Different brands and formulations have slightly different optimal tempering points due to variations in cocoa butter content and additives. Premium couverture chocolates often benefit from more precise measurement than compound chocolates.

How much does ambient temperature affect temper measurements?

Significantly. Ambient temperature impacts both the accuracy of measurement tools and the behavior of chocolate during tempering. Measure and control room temperature as part of your tempering protocol, ideally maintaining 65-70°F (18-21°C).

Are there any emerging technologies for chocolate temper measurement?

Several innovations are developing, including:

-

Ultrasonic crystal structure analysis

-

Spectroscopic methods for molecular arrangement detection

-

Machine learning systems that predict temper quality from multiple data points

-

IoT-connected measurement tools that provide remote monitoring and historical data analysis

Conclusion: The Value of Precision in Chocolate Craft

Investing in appropriate tools for measuring chocolate temper accuracy represents a significant step toward consistently excellent results in chocolate work. While experienced chocolatiers can often recognize proper temper through traditional tests, objective measurement tools provide advantages across skill levels:

-

For beginners, they provide clear guidance and reduce frustration

-

For professionals, they ensure consistency and quality control

-

For educators, they demonstrate principles of chocolate crystallization

-

For innovators, they enable experimentation with new techniques and formulations

The most effective approach often combines multiple measurement methods—using digital thermometers for basic temperature monitoring while incorporating visual tests and potentially more advanced tools as skill and production requirements grow.

Whether using simple digital thermometers or sophisticated temper meters, understanding the science behind the measurements transforms these tools from mere gadgets into essential instruments in the pursuit of chocolate perfection.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.